How to choose milling cutter pitch

When choosing the most suitable number of effective cutting edges, zc, for the operation, it is also essential to consider the pitch – the distance between the cutting edges.

Selecting the correct milling cutter pitch is important because it has a dramatic effect on productivity, stability and power consumption.

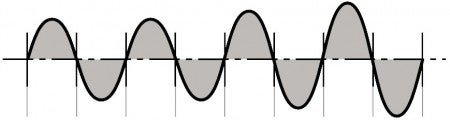

Number of cutting edges, zn

Cutter with high number of

cutting edges

By increasing the number of cutting edges, the table feed can be increased while retaining the same cutting speed and feed per tooth, without generating any more heat at the cutting edge.

However, increasing the number of edges changes the design of the tool. Shorter distances between tool edges means that there is less space left for chip evacuation and, in most cases, the cutter must be evenly pitched.

Power requirement is often a factor that limits the possible number of cutting edges that are engaged in cut.

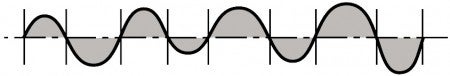

Differential pitch

Differential-pitched cutter

Differential-pitched cutters have unequal spacing of the teeth around the cutter. These cutters are advantageous because they break up harmonic vibrations, which in turn increases stability and reduces the risk of vibration. This is especially useful when milling with a high width of cut, ae, and long overhangs.

Normal pitch

Differential pitch

Coarse, close and extra-close pitch

There are normally three different pitches to choose from that can help you optimize the application: coarse, close and extra-close pitches.

The closer pitch cutters are used when stability is good and for low ae applications. This ensures that more than one tooth always is engaged in cut.

Coarse pitch

Close pitch

Extra-close pitch

Coarse pitch milling cutters, -L

Differential-pitched cutters with a low number of edges.

- First choice for unstable operations, due to lowest cutting forces

- Limited power

- Extended tooling

- Full slotting operations

- Long-chipping materials ISO N (large chip pocket)

Close pitch milling cutters, -M

Even or differential-pitched cutters with a medium number of edges.

- First choice for roughing in stable conditions

- Good productivity

- Good chip space for roughing in ISO P, M and S materials

Extra-close pitch milling cutters, -H

Even-pitched cutters with a maximum number of inserts.

- First choice for high productivity with low ae – more than one tooth is always engaged in cut

- Roughing and finishing in ISO K materials

- Roughing in ISO S materials in combination with round inserts

Note: An X added to the code describes a cutter version that has a slightly closer pitch than its basic design

How to choose thread milling cutters

Single or multi-row thread milling concepts are suitable for different applications. Single... chevron_right

Vibration

Milling vibration can arise due to limitations in the cutting tool, the holding tool,... chevron_right

Shoulder milling

Shoulder milling operations include: Shoulder / face milling Edging peripheral... chevron_right

Milling different materials

Milling steel The machinability of steel differs depending on alloying elements,... chevron_right