Plunge milling

What is successful plunge milling?

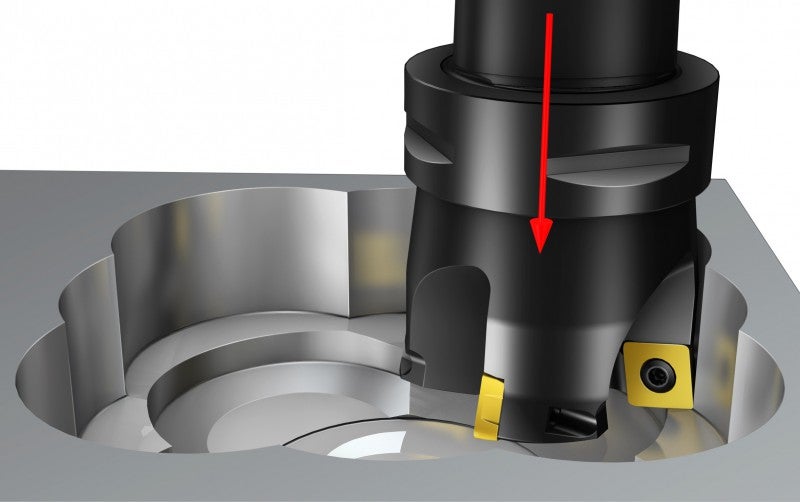

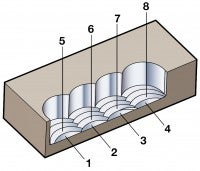

In plunge milling, the cutting is performed at the end of the tool instead of at the periphery, which is advantageous due to the change in the cutting forces from a predominately radial to axial direction. In general, plunge milling is an alternate method when side milling is not possible due to vibrations.

For example:

- When the tool overhang is greater than 4 x DC

- When the stability is poor

- For semi-finishing corners

- For difficult-to-cut material, such as titanium

It can also be an alternative when machine power or torque is a limitation.

Note: Under favorable conditions, plunge milling is not the First choice due to a lower metal removal rate.

Choice of tools

Cutter selection is determined primarily by the diameter.

Plunge drilling

Plunging with drilling tools can be more effective up to approx. DC = 35 mm, see Drilling.

How to apply plunge milling operations

Cutting process

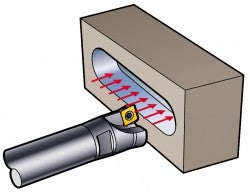

Plunge milling operations vary considerably from traditional milling. They use the end of the tool to cut instead of the periphery, which beneficially changes the cutting forces from a predominantly radial to axial direction. It can be compared to a boring operation with interrupted cuts.

Power consumption and noise are low.

Plunge milling = interrupted boring.

Axial cutting forces.

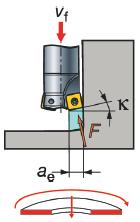

Traditional milling.

Mainly radial forces.

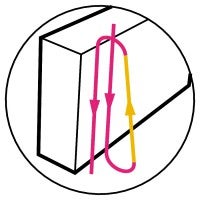

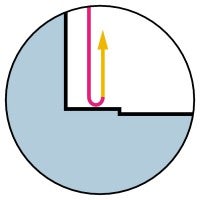

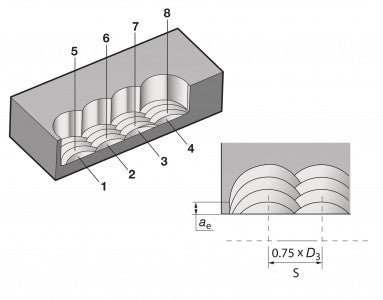

= program table feed

= rapid traverse

Avoid re-cutting on return stroke. Gradually decrease plunge depth.

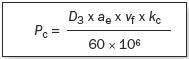

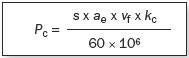

Power consumption calculation.

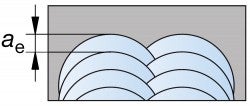

Feed in plunge milling

| Feed in plunge milling | ||

| Insert size | Overhang < 3 x DC | Overhang > 3 x DC |

| 9 | fz = 0.15 (0.10–0.20) | fz = 0.10 (0.08–0.15) |

| 14 | fz = 0.20 (0.10–0.25) | fz = 0.15 (0.10–0.20) |

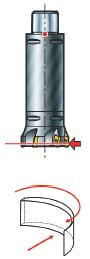

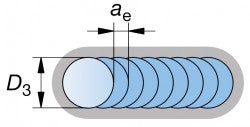

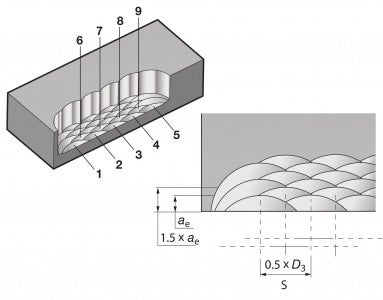

Oversized cutter L ≤ 3 x DC

| iC | max ae |

| 9 | 8 |

| 14 | 13 |

s = 75% DC

Oversized cutter L ≥ 3 x DC

| iC | max ae |

| 9 | 7 |

| 14 | 12 |

s = 50% DC

ae = max for insert

Side step s = X% DC

* S is tool overhang specific

Plunge milling tips

- A horizontal machine facilitates chip evacuation

- Start milling from the bottom and work up

- Use cutting fluid or compressed air to facilitate chip evacuation

- In comparison to traditional methods, plunge milling requires a lower feed per tooth

- Ensure that more than one tooth is engaged

- Use extra-close pitch cutters

- Use maximum ae – depending on insert size

- Use s = 0.75 x DC when moving sideways

- Gradually decrease plunge depth to minimize vibration

- Use a "hook program" to prevent re-cutting on the return stroke. Feed 1 mm away from the wall at the end of the cut

- Note: A drilling cycle is not recommended due to re-cutting, which can cause vibration during retraction

- Always strive to leave a constant stock for a subsequent finishing operation

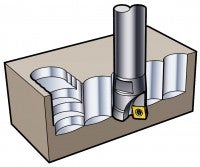

Slots

- Plunging is an effective technique for machining deep and closed slots

- Chip evacuation becomes essential. A horizontal set-up and the use of cutting fluid or compressed air will assist in this process

- A drill is recommended for deep and narrow slots, as it provides the best chip evacuation and highest step-over rate

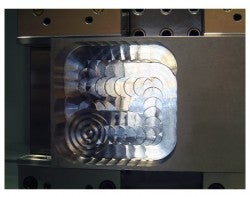

Cavities/pockets

- Chip evacuation is critical, just as in closed slotting

- Use a horizontal set-up and cutting fluid or compressed air

- Chip evacuation can be further improved by riling the largest possible start hole. 1.5 x DC is recommended

- Reduce feed in the first two plunge steps

- Move sideways and try to prevent full slotting

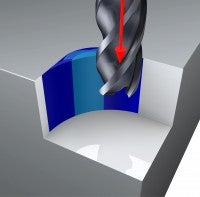

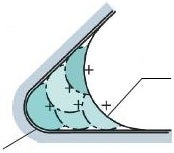

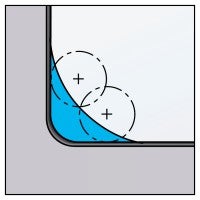

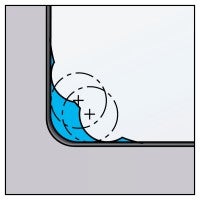

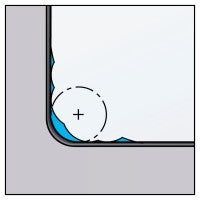

Corners

Plunge milling of the remaining stock (rest milling) after a roughing operation in deep 90 degree corners can be advantageous.

DC = 12.7 mm

Start radius = 16 mm

End radius = 6 mm

Corner machining

Plunge drilling

What is plunge drilling? Plunge drilling is an effective method for roughing out... chevron_right

Milling holes and cavities/pockets

Two-axis ramping linear Circular ramping Widening a hole Circular external milling... chevron_right

Profile milling

Profile milling is a common milling operation. Round inserts and concepts with radius... chevron_right

Milling inserts and grades for titanium and HRSA

This is a PVD-coated carbide grade optimized for titanium milling; excellent for... chevron_right