What is successful milling?

When evaluating a successful outcome within milling applications, it is very much dependent on several key factors such as process and component features, roughing versus finishing operations, productivity demands versus quality of component (i.e., dimensional accuracy, geometric shape, and controlled surface finishes), and process capability according to customer priorities. However, a successful milling outcome is one that fulfills its quality requirements within an optimized, predictable, productive, and secure repetitive process.

Milling has evolved into a method that machines a very broad range of operations. In addition to all the conventional applications, milling is a strong alternative for producing holes, threads, cavities, and surfaces that used to be turned, drilled, or tapped.

Different types of milling operations

- Shoulder milling

- Face milling

- Profile milling

- Groove milling and parting off

- Chamfer milling

- Turn milling

- Gear machining

- Holes and cavities/pocketing

Initial considerations for milling operations

1. The milled configuration

The features to be milled have to be carefully considered. These can be located deep, requiring extended tooling, or contain interruptions and inclusions. Different requirements will guide our tool selection, including tool concept, effective teeth, use of coolant, grades, and geometries.

2. The component

Workpiece surfaces can be demanding, with cast skin or forging scale. In cases of poor rigidity, caused by thin sections or weak clamping, dedicated tooling and strategies have to be used. The workpiece material and its machinability must also be analyzed to establish optimal cutting data.

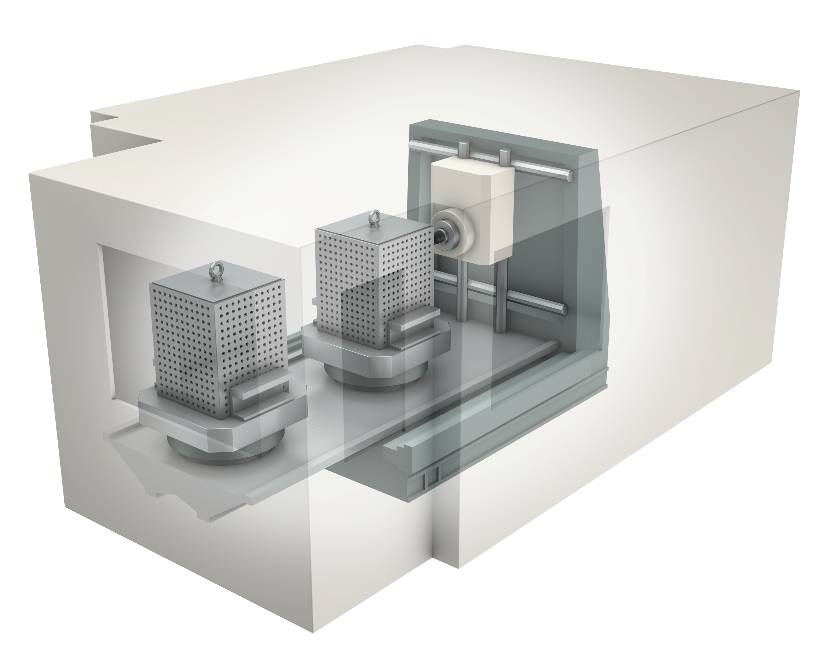

3. The machine

The choice of milling method will determine the type of machine needed. Face/shoulder or slot milling can be performed in 3-axis machines, while milling 3D profiles requires 4- or 5-axis machines.

Turning centers today often have milling capability due to driven tools, and machining centers often have turning capability. CAM developments mean that 5-axis machines are increasingly common. They offer increased flexibility, but stability can be a limitation.

Plunge drilling

What is plunge drilling? Plunge drilling is an effective method for roughing out... chevron_right

Ramping: Two axis linear and circular

What is successful ramping? Linear ramping is a commonly used, efficient way of... chevron_right

Five Questions with Dan Tucker

Sandvik Coromant: Some may say that Sandvik Coromant is only a turning company, but... chevron_right

Cutting tool materials

Introduction The selection of the cutting tool material and grade is an important... chevron_right