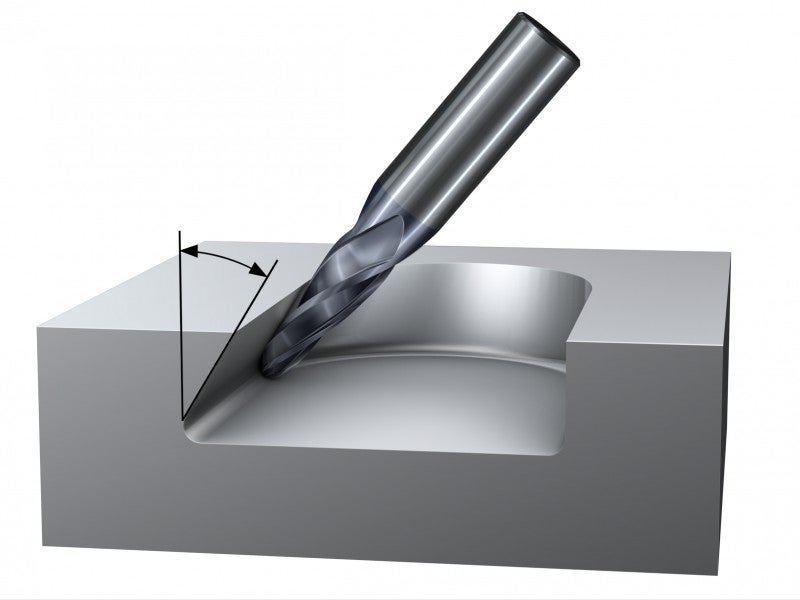

Milling closed pockets or angles

Closed angles, less than 90 degrees, are a common component feature in pockets and cavities. A 4- or 5-axis machine is needed to machine a closed angle.

Milling a blisk impeller is one

application example of milling closed angles.

Use a 4-axis machine:

- If only one side of the pocket has a closed angle and the bottom shape is flat

Use a 5-axis machine:

- If there are corners with closed angles on both sides

- If the bottom profile has a radius

How to mill closed pockets or angles

Machining recommendation

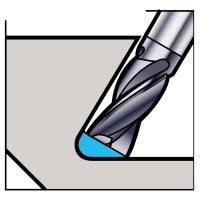

- Prior to radius machining, shoulder milling of the wall should be performed with a square end mill for best stability.

- The radius is machined with a ball nose end mill.

Use a square end mill for

best stability when machining

the peripheral wall.

The final machining of the radius

should be performed with a conical

ball nose end mill.

Pylon brackets

The pylon brackets found on the wing of the aircraft can have an open or closed design.... chevron_right

Milling holes and cavities/pockets

Two-axis ramping linear Circular ramping Widening a hole Circular external milling... chevron_right

Groove or slot milling

Groove or slot milling is an operation in which side and face milling is often preferred... chevron_right

Ramping: Two axis linear and circular

What is successful ramping? Linear ramping is a commonly used, efficient way of... chevron_right