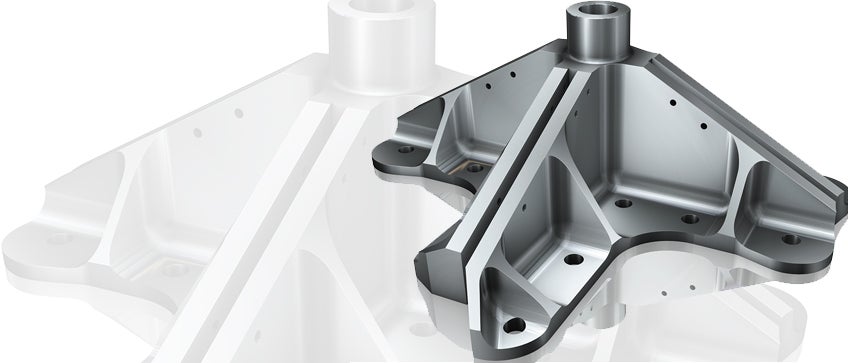

Solutions for cost effective and high-quality machining of aerospace thrust fitting in titanium

The thrust fitting is normally produced in titanium and is located between the wing and the engine. The main challenge is the machining with long overhang tools.

Tooling solutions for aerospace thrust fitting

CoroMill® MS20 – pocketing

- M-M20 geometry gives higher security in tougher applications

- In case of sensitive / vibration prone applications and / or applications requiring a sharper cutting edge, the E-L50 geometry can be used

- The higher edge line toughness of these geometries allows the inserts to be used with higher productivity (high cutting data) in stable operations

- Robust steel shank design ensures better stability and less deflection. The improved tool body material can withstand chip rubbing better

CoroMill® 690 - developed specifically for high-productivity 2D profile milling of titanium components

Inserts are securely fastened by iLock technology. By equipping every insert pocket with threaded coolant holes with nozzles for high pressure coolant delivery, you can apply maximum coolant where required.

2D profile milling long overhang

The Coromant Capto® modular tool holding system enables tools to be assembled to the required length, while maintaining high stability and smallest run-out. Keep the tooling assembly as rigid and short as possible. Choose the largest possible adaptor diameter/size. Use Coromant Capto adaptors with oversized cutters to avoid reduction adaptors. For small milling cutters, use a tapered adaptor if possible.

Coromant Capto® modular tool holding system

Silent Tools™ - tool holding designed to minimize vibrations in long overhang machining