Solutions for cost effective and high-quality machining of aerospace flap track

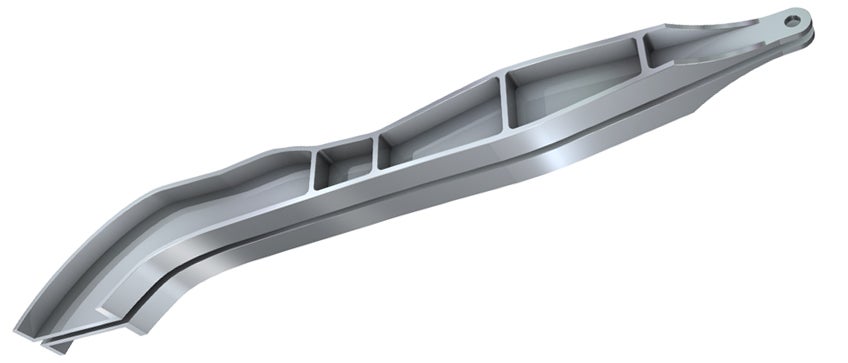

The flap track is located in the trailing edge mechanism. This component is normally produced in stainless steels such as 15-5 PH etc.

CoroMill® MS20 – pocketing

- M-M20 geometry gives higher security in tougher applications

- In case of sensitive / vibration prone applications and / or applications requiring a sharper cutting edge, the E-L50 geometry can be used

- The higher edge line toughness of these geometries allows the inserts to be used with higher productivity (high cutting data) in stable operations

- Robust steel shank design ensures better stability and less deflection. The improved tool body material can withstand chip rubbing better

CoroMill® MH20 – High feed pocketing

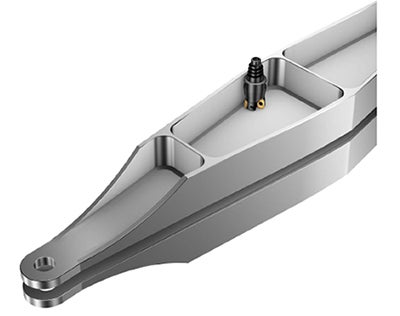

When machining deep pockets, especially narrow deep pockets, long overhangs are required. This condition is challenging and there is a high risk of vibrations. CoroMill® MH20 is optimized for pocketing applications in ISO S, M and P materials and ensures secure and vibration-free machining with long overhangs.

CoroMill® 390 - Milling of 2D pocket and 2D profile milling

CoroMill 390 end mill - size 17 mm insert, together with grades GC2040/GC4240 is an ideal choice for the 2D roughing of the pocket. The size 17 insert comes in a radius range of 0.4- 6.4 mm.

The best choice for roughing the 2D profile is CoroMill 390 long edge with 18 mm size insert and specialized grades GC2040 and GC4240. The CoroMill 390 with 18 mm insert has a tougher edge for higher feeds and heavier applications. It is also available in a wide range of radius inserts.

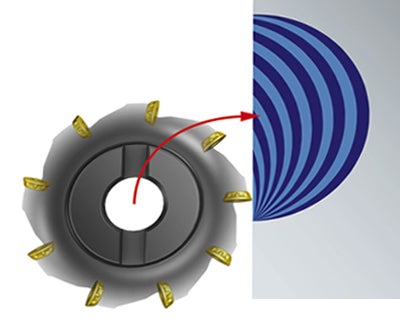

CoroMill® 345 - Face milling

Enter the workpiece smoothly with CoroMill® 345 by lowering feed to 50% until the cutter is fully engaged. This high performance tool is equipped with an 8-edged insert for the best economy and productivity.

CoroMill® 345 (up to diameter 125 mm) has coolant supply to each insert pocket ensuring good chip evacuation for the best performance when machining demanding materials.

CoroMill® 331 – Slotting solution

The CoroMill 331 is the ideal solution when machining the deeps slots in the flap track. Spring-loaded cassettes provide easy setting for desired width. Cutters are delivered within 0.01 mm width. To achieve a close tolerance, use the H tolerance inserts. Round insert options and a vast assortment of corner radii.