Solutions for cost effective and high-quality machining of aluminium wing rib

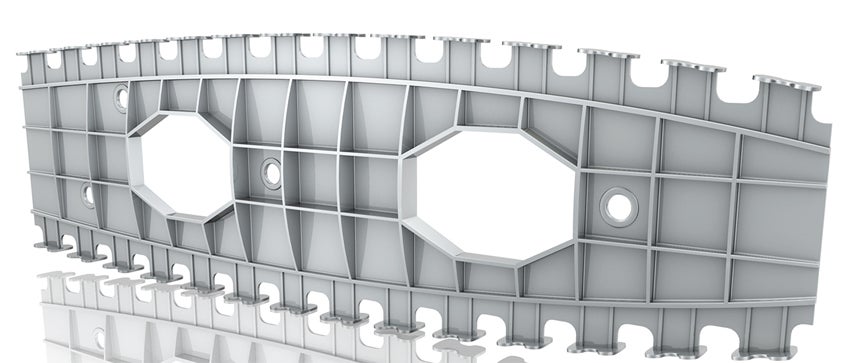

There are several types of aluminium components on an aeroplane such as spars, skins, and ribs. The wing rib as an example shows some of the machining challenges such as thin walls/bases, 2D pockets and the importance of balanced tools.

Tooling solutions for aerospace Wing rib

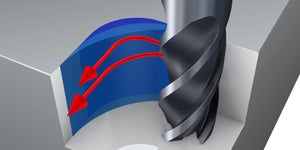

Thin wall machining

The machining strategy for thin wall sections should vary depending on the height and thickness of the wall. The number of passes will be determined by the wall dimensions and axial depth of cut.

Use of high speed techniques, i.e small ap/ae and high vc facilitates milling of thin walls, as they reduce the time of tool engagement and consequently the impulse and deflection. Step support machining the wall in overlapping passes is used when wall thickness vs height are 15:1 to 30:1.

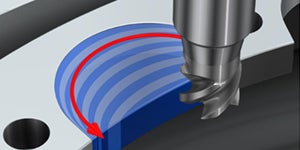

CoroMill® 316 and CoroMill® Plura - Corner milling - slicing

Slicing is a method used in corner milling where multiple passes successively remove material ensuring low radial immersion/ engagement angle and low cutting forces. By applying the dedicated aluminium geometries for CoroMill® Plura or CoroMill 316 with high speed machining techniques, extreme productivity increases can be made.

Pocketing with high speed aluminium router RAL 90

The RAL90 aluminium milling cutter sets the standard for a new level of stability in high speed milling. Optimized for high power spindles, this milling cutter offers unique metal removal rates. The accuracy of the insert seat interface secures the position of the cutting edge, minimizing total tool run-out. Tailor Made® service gives you the freedom to specify your own tool dimensions.

In applications requiring even more power and higher metal removal rates, the new RAL90 Super MRR can reach extra high spindle rotation, e.g. up to 33000 RPM for DC 50 mm compared to 23500 RPM for RAL90. This equates to a 40% increase in productivity. RAL90 Super MRR is designed with couplings dedicated for specific machine tool makers