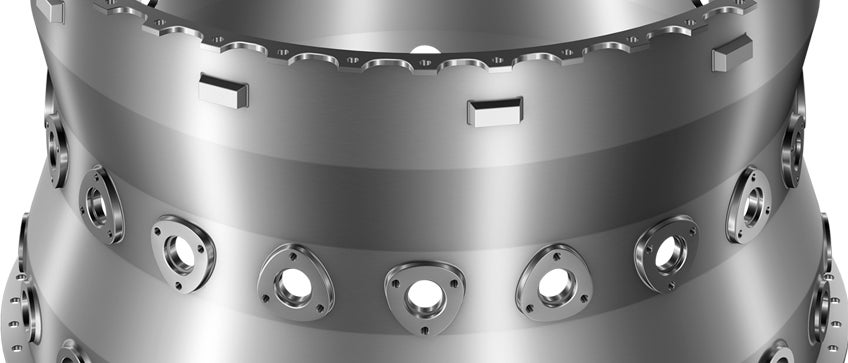

Solutions for cost-effective and high-quality machining of aerospace combustion casings

Typically made from Inconel or Waspaloy, these most challenging of materials pose difficulties, not so much in the turning operations, but particularly with the amount of milling required in manufacturing this component and the large amounts of material to be removed.

Tooling solutions for aerospace combustion casings

CoroMill® Plura solid carbide end mills for high feed face milling and full slotting

CoroMill® Plura is a range of high-quality solid carbide end mills that offer productive, efficient and perfectly reliable milling solutions.

CoroMill® Plura with grade 1610 provides exceptional metal removal rates in full slotting and roughing operations with large cutting width. Thanks to the optimized face geometry, more than double the feed per tooth can be achieved compared to regular end mills.

CoroMill® Plura HFS solid carbide end mills for semi-finishing with high feed side milling

Utilize CoroMill® Plura HFS high feed side milling tools for reliable and productive milling. The optimized grade for nickel-based alloys have sharp, controlled cutting edges, providing long and predictable tool life along with high metal removal rate.

High speed super finishing and finish bore with CoroMill® Plura end mill

High speed super finishing with CoroMill® Plura with grade 1610 provides high productivity due to the large number of flutes.

Circular interpolation can be used as a fast and secure method for finish bore. With this approach, one tool can finish a wide range of hole diameters, reducing tool inventory.

CoroMill® Plura thread mills and CoroTap® tapping tools - For reliable threading and tapping

The CoroMill® Plura and CoroTap® threading and tapping solutions for nickel-based alloys provide excellent process security when working with high value components.

CoroTap® 300 is a tap with spiral flute grinding. The tool offers excellent chip evacuation in blind holes.

Semi-finishing and finishing with CoroMill® 390

CoroMill® 390 end mills with size 07 inserts can be successfully used for machining of stock left after roughing around bosses, leaving excellent surface finish on casing floor.

CoroMill® 300 light-cutting face and profile milling cutters

Helical ramping of larger diameter holes with CoroMill® 300 is a very secure and productive method in this case. The cutting forces are much lower than for drilling operations, which also struggles with the interrupted exit into the bore.

For rough milling around a boss, use CoroMill® 300 with a roll-in programme combined with round inserts to reduce notch wear and allow high feed rates.

CoroMill® 600 versatile round insert profile milling cutter

The positive axial angle and optimized cutting action make CoroMill® 600 particularly suitable for heat-resistant materials.

The unique iLock® solution provides easy and accurate insert indexing, increased reliability and considerably improved tool life.

Highly secure drilling with CoroDrill® 860

CoroDrill® 860 with -SD geometry is a short-hole drilling solution optimized for machining nickel-based ISO S materials. This drill offers consistent and predictable tool life with high dimensional accuracy and excellent hole quality.

Optimized chip control with CoroDrill® DS20

CoroDrill® DS20 is the first indexable insert drill that can reach hole depths from 4 up to 7×DC with no need for pilot drilling.

The innovative drill body and insert design allows for reliable and predictable drilling while the stable and high precision Modular Drilling Interface provides excellent centring capabilities and reduced overall tool inventory.

Internal machining of small high-quality features with CoroTurn® XS

CoroTurn® XS is a system for solid carbide tools designed for exact cutting edge position, enabling high precision and repeatability in turning machining.

This tool replaces inflexible special tools and can be used not only for holes but also for all de-burring.

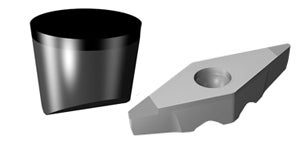

Grade S30T – designed for challenging super alloy machining

Grade S30T is a PVD-coated carbide grade optimized for titanium milling; excellent for finishing to light roughing. This thin-coated grade enables very sharp cutting edges that resist fatigue and micro-chipping, allowing the cutting edges to be preserved for longer time in cut at higher cutting speeds.

CoroCut® angled inserts

Designed specifically for reaching difficult to access grooves and pockets in complex components.

Ceramic turning

Ceramic grades CC6220 and CC6230 are optimized for the challenges of new HRSA materials where whisker ceramics and SiAlONs fall short. The grades allow higher cutting speeds, contributing to reduced cost per component. For high metal removal rates in pocketing and profiling applications, choose grade CC6160. For more demanding HRSA surfaces, choose the tougher grade CC6165.

CB7014 high speed CBN turning solution for nickel-based alloys

Finish turning of aerospace components are challenging operations performed in demanding ISO S materials. Using CBN inserts allows for increased cutting speed and improved productivity while maintaining good surface integrity on the component. CBN inserts optimized for high speed finishing of nickel-based heat resistant super alloys are now available as a stocked standard solution.

CoroTurn® 107 with rail interface for profiling and pocketing in HRSA materials

For finishing in HRSA components with relatively open features it is optimized to use the positive, screw-mounted CBN insert. With up to 12 insert indexes it will boost your productivity in HRSA materials. The rail interface ensures mounting security, offers process security and increases reliability and tool life for your profiling and pocketing operations.

Grades optimized for turning of aged nickel-based HRSA

Turning grades GC1205 and GC1210 provide secure and reliable machining with excellent flank and notch wear resistance. A combination of a hard substrate and PVD coating allows for a significant increase in cutting speed (GC1205) and tool life (GC1210).

- GC1205: Finishing grade for machined surfaces. For last stage machining and intermediate stage machining applications

- GC1210: Mainly used in intermediate stage machining applications. Complements GC1205 when more toughness is required