Solutions for cost effective and high-quality machining of aerospace vertical tail

The main challenges for machining these types of structural components are the hole making, edging and surface machining.

Tooling solutions for aerospace vertical tail

Composite solutions – product offer for composite machining

Machining solutions dedicated to specific composite materials as well as operations and demands are becoming an increasingly important competitive factor.

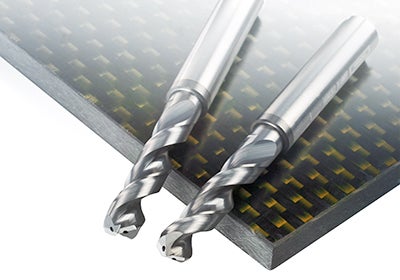

CoroDrill® 863 with -O geometry - solid carbide drills for high quality hole making and longer tool life in composite

Hole making in CFRP (carbon fibre reinforced polymer composite) - facts and demands

- Unidirectional and woven carbon fibre

- Minimal delamination of fibres

- Good surface finish and dimensions

Solutions

- CoroDrill® 863 with -O geometry, standard diameter range 3–9.5mm (0.118–0.374 inch)

- Drill depth 3–10 × drill diameter

Benefits

- Enhanced tool life – more metres of composite material drilled

- Minimal delamination

- Excellent hole finish and tolerance

Cutting data

- Visit CoroPlus® ToolGuide for precise cutting data suggestion