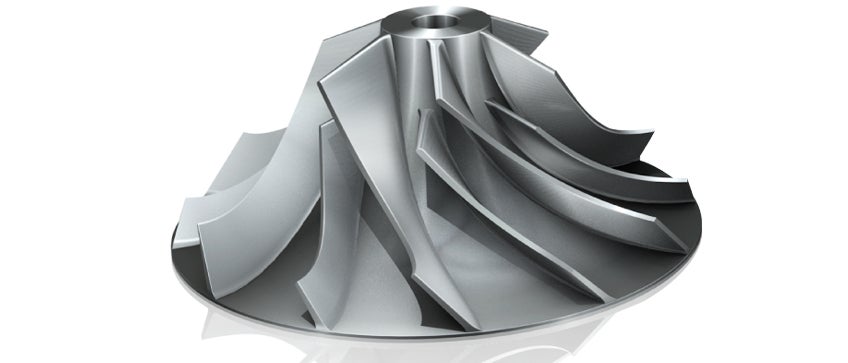

Solutions for cost effective and high-quality machining of aerospace impellor in titanium and HRSA

The impellor is found in the APU. The machining of the turbo foils is a similar process for both impellor and blisk.

Key factors to success are:

- 5 axes machine with good simultaneous dynamics

- Turbo 5 axes CAM software

- Optimized tools and process knowledge for titanium/HRSA

Tooling solutions for aerospace impellor in titanium and HRSA

CoroMill® 316 - Plunge roughing of slot

Machining components with slots and pockets is always challenging. With the CoroMill® 316 Gannet plunger geometry available to order off the shelf, manufacturing of small, deep slots and pockets is both time- and cost efficient.

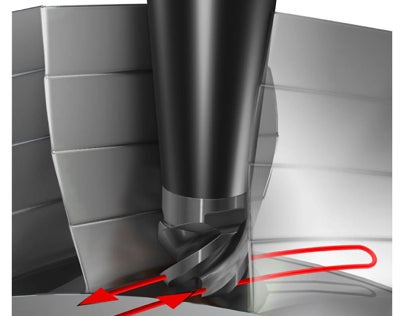

Roughing slot - titanium

The best method here is point milling. Because we are full slot milling the axial depth of cut is limited to half the diameter of the tool. The CoroMill® 316 ball nose exchangeable insert offers a great balance of productivity and economy.

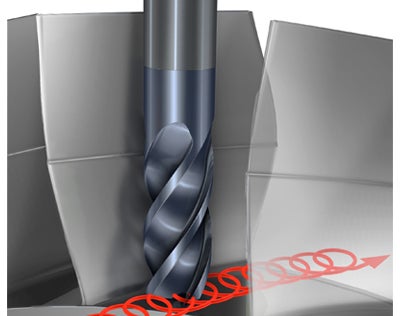

Roughing slot – Inconel

Applying trochoidal milling with high speed machining techniques is the best method. Trochoidal milling – 2D roughing/high material removal method using HSM techniques in a confined space or slot – tool is programmed with a roll entry and exit from cut:

- controlling the arc of engagement

- low cutting forces allowing high depths of cut

CoroMill® Plura 50 degree relieved shank, ball nose design, is optimized for axial depth of cut twice the diameter and low radial cuts.

CoroMill® Plura solid carbide ball nose end mill for profiling

Semi-finishing and finishing the blade profile

Flank milling (high axial depth of cut) is the fastest method when the component, CAM software and the tool allow.

CoroMill® Plura conical ball nose is optimized for this operation. The tapered design and ball nose feature combine to reach the toughest spots with unmatched accuracy and high quality.

CoroDrill® 860 with -SM geometry

When drilling tough ISO S materials, many factors need to be taken into account. Process security, repeatability, hole tolerance and quality are critical. Equipped with a robust design, a high-quality edge and a wear-resistant top coating, the CoroDrill® 860 with -SM geometry delivers on these key considerations.

Finish bore with CoroMill® Plura end mill

Circular interpolation is a fast and secure method, one tool can finish a wide range of hole diameters reducing tool inventory.

Chamfer with Coromant Capto CoroTurn® XS

This tool replaces inflexible special tools and can even be used for all de-burring and not just holes.

CoroChuck™ 930

Thanks to its excellent clamping performance this chuck offers the best pull-out security on the market, for excellent stability and accessibility in milling and drilling operations. A solution that doesn’t just helps increase machining safety and precision, but also increases production efficiency through quick and easy tool set-ups and changes. For 100% pull-out prevention, a collet with mechanical locking interface is available for Weldon shanks.