How to choose a machine spindle

Choosing a machine spindle interface is a key decision, as this often defines the limitations on metal-cutting efficiency. There is no quick answer to which interface is best—it really depends upon the components to be machined and the operations being carried out. It should not be assumed that the standard spindle options with a machine are necessarily the best interface choice.

Machine spindle requirements

When not machining, the machine spindle interface requires quick interchangeability. Yet when machining, it is vital that the joint between the machine spindle and coupling is solid, even if cutting forces do their best to disrupt this interface. It is important to have an interface that offers good bending stiffness and torque capabilities.

- Bending stiffness: Required for a stable cutting process with long tool overhangs or with heavy cutting loads

- Torque transmission: Large-diameter operations are most sensitive. The load applied at a distance away from the spindle center line (torque = force x radius) needs to be countered by a greater driving contact area.

- Accurate tool center position: To provide repeatability and secure production, which is especially important for turning operations

The coupling characteristics for withstanding high bending or radial cutting forces are:

- Flange contact diameter: Flange face contact increases the platform base, reducing the leverage of the cutting force

- Clamping force: The greater the clamping force to restrain a coupling, the greater the cutting force required to “topple” the coupling

- Cross-sectional area: Reduction of the tool diameter relative to the flange contact diameter will reduce the stiffness of the tool

- Torque transmission: Most clearly evident with large diameter tools and turning, an inability to withstand torque will immediately mean loss of center height and precision

Machine spindle interface history

The machine spindle interface has evolved with the evolution of machines. Some of the key milestones that influenced the changes are:

- NC control leading to automatic tool changing and tool storage. This led to the steep taper adopting pull studs and gripper grooves

- Higher spindle revolutions

- Multifunctional machining, turning, milling and drilling with the same interface

The well-known, first interface was the Morse Taper, developed for drilling as long ago as 1868. Thereafter, the steep taper 7/24, also called the ISO taper, was introduced in 1927. Gripper grooves and pull studs were added for tool change in the 60s, with three regional variations: MAS-BT in Asia, ISO/DIN in Europe and CAT-V in America.

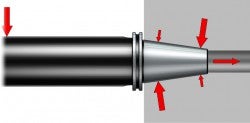

The downside with the steep taper is bending stiffness and rpm capability due to a low clamping force and lack of face contact with the spindle nose. This led to new developments in the 90s with BIG-PLUS® (developed in Japan by BIG Daishowa), HSK (developed in Germany by the DIN committee) and Coromant Capto® (launched in 1990 and the only system developed for all types of applications—turning, milling and drilling—from day one).

Machine spindle interface types

The table below shows the four main couplings and a step-by-step evolution from the traditional steep taper to Coromant Capto®. All interfaces, except BIG-PLUS®, are standardized as DIN, ISO or ANSI.

| Taper angle | Flange contact | Clamping method | Torque transmission | |

| Steep taper | 16.26° | No | Pull stud | Drive keys on flange contact |

| BIG-PLUS® | 16.26° | Yes | Pull stud | Drive keys on flange contact |

| HSK-A | 5.7° | Yes | Internal segment clamping | Drive keys on taper |

| Coromant Capto® | 2.88° | Yes | Internal segment clamping | Polygon |

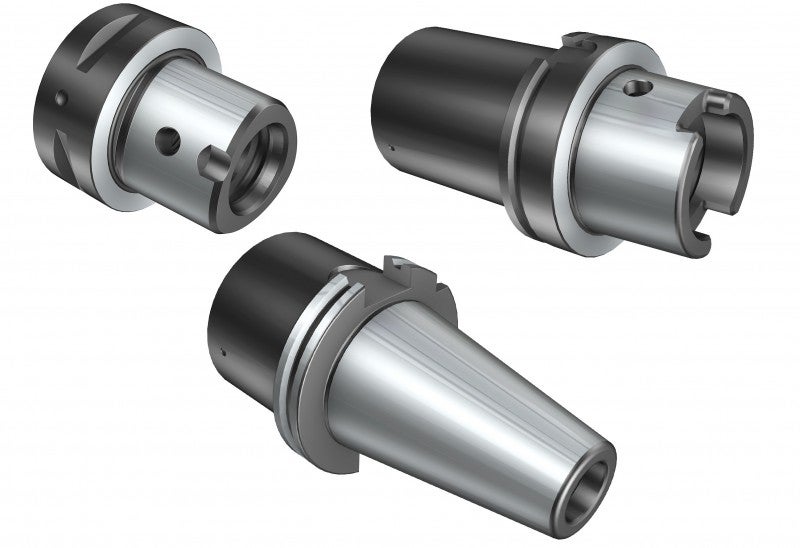

Steep taper

BIG-PLUS®

HSK-A

Coromant Capto®

Steep taper 7/24

For steep tapers, the taper angle is always the same. Gripper groove and thread for the pull stud can vary. Available as CAT, ISO, DIN and MAS BT.

BIG-PLUS®

BIG-PLUS® is developed for machining center applications. The taper and gripper groove is the same as the traditional steep taper; however, through tight tolerances, face contact is achieved, increasing bending stiffness. A standard steep taper holder can fit in a BIG-PLUS® spindle, however, mixing is not recommended. Available as CAT, ISO, DIN and MAS BT.

HSK

HSK (DIN 69893) is developed for machining centers. It features flange contact and hollow taper segment clamping, eliminating the need for pull studs. The drive keys have various configurations depending on the variant, and in some cases none, for high-speed applications.

- Type A: General machining, high bending loads and moderate torque, automatic tool change

- Type B: Stationary application, moderate bending loads, high torque, special applications, automatic tool change

- Type C: General machining, high bending loads and moderate torque, manual tool change (Ref. Type A)

- Type D: Stationary application, moderate bending loads, high torque, special applications, manual tool change (Ref. Type B)

- Type E: High-speed application, light and fast spindles, low bending moments and torque, automatic tool change, easy balance

- Type F: Moderate-speed applications, machining of soft materials, medium bending moments and torque, automatic tool change, easy balance

- Type T: Rotating and static applications with tighter tolerances in the driving slot (for tool positioning). No "neck" is required; therefore, bending moment abilities are improved

Note! Most machines stating HSK-T spindle interface still require the neck for automatic tool changing and magazines—this means that HSK A/C/T tools are required

A

B

C

D

E

F

T

A/C/T

Coromant Capto®

Coromant Capto® (ISO 26623) covers the benefits of both HSK and BIG-PLUS®, but has removed the need for drive keys by instead driving through a tapered polygon with face contact. The strong coupling cross section provides room for segment clamping with the highest clamping force capabilities, providing unrivaled bending stiffness, torque transmission and center position accuracy.

The improved radial precision and torque transmission was required to cover the demands for the three target application areas:

- Machine spindle interface – machining centers and vertical lathes

- Modular coupling – machining centers

- Manual quick change system – lathes

Coromant Capto® is the most common interface for multi-task machines, as it can cope with both static (turning) and rotating (milling/drilling) applications.

Machine spindle recommendations for different machine types

Machining centers (only rotating)

It is recommended to use a spindle interface with face contact. BIG-PLUS® and HSK-A provide good-enough stability for the majority of rotating applications in machining centers. For heavy-duty applications, Coromant Capto® C10 should be considered before a larger coupling such as HSK-A 125 or SK60. For high rpm applications, HSK-E or F should be considered.

Multifunctional machines (static and rotating)

Coromant Capto® is the only coupling capable of handling the torque and bending stiffness requirements for static and rotating applications.

There are different spindle clamping mechanism solutions, as well as spindle interface production. Sandvik Coromant works actively with machine tool builders to support integration of Coromant Capto® into machines. The primary focus is on the machine styles and interfaces below, where the benefits of Coromant Capto® are the greatest.

| C3 | C4 | C5 | C6 | C8 | C10 | |

| Turning center | * | * | ||||

| Heavy-duty lathe | ||||||

| Vertical turning lathe | ||||||

| Multi-task machine | ||||||

| Machining center with turning | ||||||

| Machining center, heavy-duty |

* Long boring bars on large turning centers

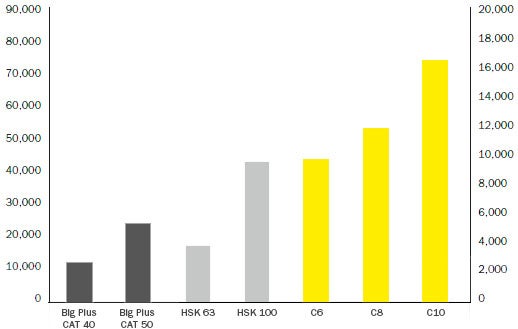

Clamping force comparison

The internal segment clamping used for hollow tapers (HSK and Coromant Capto®) can provide higher clamping force than the pull stud can provide on a steep taper. The table shows the clamping force applied to the respective interfaces. The increased cross-sectional area and coupling length of Coromant Capto® allows for much higher clamping forces compared to HSK-A.

Sources: HSK Handbook, copyright 1999.

Big Daishowa (Big plus spindle system.)

Coromant Capto®

HSK-A

Steep taper (SK)

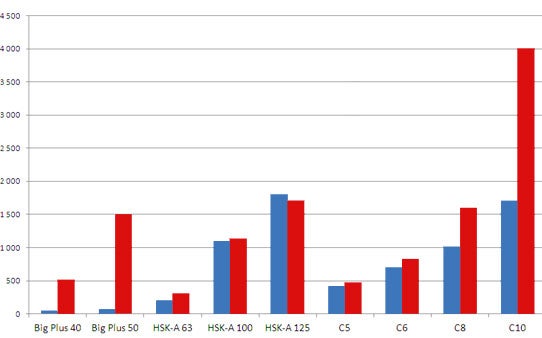

Torque transmission and bending stiffness comparison

Steep taper – the drive keys on a large radius provide good drive for rotating applications

HSK-A – a small contact area with the slots on the taper rather the flange diameter (small radius); not recommended for high-torque applications.

Coromant Capto® – for turning applications, center positioning accuracy is required, in which case the polygon drive provides the best capability.

The size of the coupling will provide limitations on bending stiffness and maximum rpm. A large coupling provides good stiffness, but lower rpm while a small coupling allows for higher rpm but lower bending stiffness.

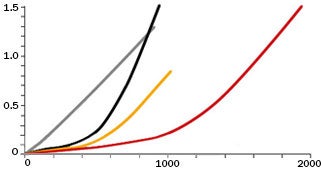

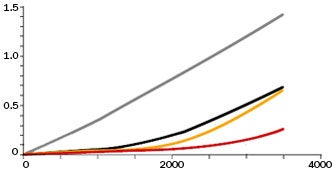

The diagram below shows the limitations on the respective couplings from theoretical (FEA) calculations for when the face contact is lost (bending stiffness) and fatigue limit is reached (maximum torque).

Blue: Maximum bending moment (Nm)

Red: Maximum torque (Nm) within fatigue limit

BIG-PLUS® and HSK provide good-enough stability for the majority of rotating applications, but for multi-task machines, Coromant Capto® is the only coupling capable of handling the torque and bending stiffness requirements.

| Coupling | Size and clamping type | Clamping force (pull stud or draw bar) | Max rpm (depending on spindle and bearings) | |

| N | lbs | |||

| BIG-PLUS® ISO/CAT/BT 7/24 taper | Taper 40 | 12000 | 2703 | 16000 |

| Taper 50 | 24000 | 5405 | 12000 | |

| HSK-A | HSK-A 63 | 18000 | 4054 | 20500 |

| HSK-A 100 | 45000 | 10135 | 12500 | |

| HSK-A 125 | 70000 | 15766 | 9500 | |

| Coromant Capto® | C5 | 32000 | 7207 | 28000 |

| C6 | 41000 | 9234 | 20000 | |

| C8 | 50000 | 11261 | 14000 | |

| C10 | 70000 | 15766 | 10000 | |

| Coupling | Size and clamping type | Clamping force(pull stud or draw bar) | Max rpm(depending on spindle and bearings) | |

| N | lbs | |||

| BIG-PLUS® ISO/CAT/BT 7/24 taper | Taper 40 | 12,000 | 2,703 | 16,000 |

| Taper 50 | 24,000 | 5,405 | 12,000 | |

| HSK-A | HSK-A 63 | 18,000 | 4,054 | 20,500 |

| HSK-A 100 | 45,000 | 10,135 | 12,500 | |

| HSK-A 125 | 70,000 | 15,766 | 9,500 | |

| Coromant Capto® | C5 | 32,000 | 7,207 | 28,000 |

| C6 | 41,000 | 9,234 | 20,000 | |

| C8 | 50,000 | 11,261 | 14,000 | |

| C10 | 70,000 | 15,766 | 10,000 |

Static test comparing bending stiffness and torque resistance

The well-reputed RWTH Aachen University in Germany carried out a series of static tests in the machine tool laboratory (WZL), comparing bending stiffness and torque resistance of the different spindle interfaces.

Coromant Capto® was measured with two clamping forces: the same as for HSK-A, (22 kN for C6 and 50 kN for C10), and then the higher standard clamping force (45 kN for C6 and 80 kN for C10).

Bending Stability

Deflection [mm/m]

Bending moment [Nm]

C6 – 45 kN

C6 – 22 kN

HSK-A 63 – 22 kN

7/24 taper, size 40 – 15 kN

Bending Stability

Deflection [mm/m]

Bending moment [Nm]

C10 – 80 kN

C10 – 50 kN

HSK-A 100 – 50 kN

7/24 taper, size 50 – 25 kN

The results show that, even with the same clamping force as HSK-A, the stronger coupling exhibited improved bending stiffness, but with the higher clamping force, the toppling force was 2.88 times better for C6 compared to HSK-A 63 and 2.15 times better for C10 compared to HSK-A 100.

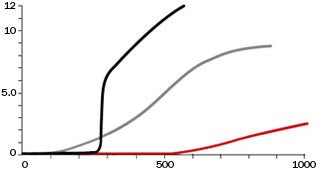

Torque Stability

Deflection [mm/m]

Torsional moment [Nm]

C6 – 46 kN

HSK-A 63 – 22 kN

7/24 taper, size 40 – 15 kN

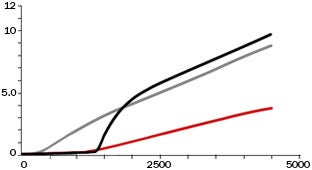

Torque Stability

Deflection [mm/m]

Torsional moment [Nm]

C10 – 50 kN

HSK-A 100 – 50 kN

7/24 taper, size 50 – 25 kN

The graphs show that Coromant Capto® C6 has 2.29 times better torque resistance than HSK-A 63. The twisting angle was 7.1 times better. Corresponding figures for C10 were 1.85 times better torque resistance and 4.0 times better twisting angle than HSK-A 100.

How to choose the infeed method

OptiThreading What is OptiThreading? OptiThreading is a method with tool oscillation... chevron_right

How to apply boring

To achieve an optimized boring process, there are several factors to consider. Correct... chevron_right

How to achieve good component quality in turning

To achieve quality turned components, chip control is one of the most important factors... chevron_right

Vibration

Milling vibration can arise due to limitations in the cutting tool, the holding tool,... chevron_right