Modular solutions

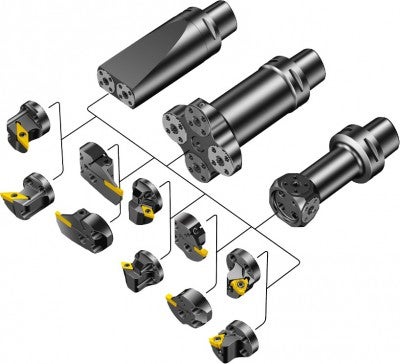

Modular tooling systems provide the ability to build an optimized and tailored assembly for a specific application using standard items. A relatively small inventory can build a huge number of combinations, allowing common tooling systems to be used throughout the factory regardless of the machine interface.

A modular system interface is an intermediate interface sitting between the machine interface and a shank or insert. Applications and machines place different requirements on a modular system interface.

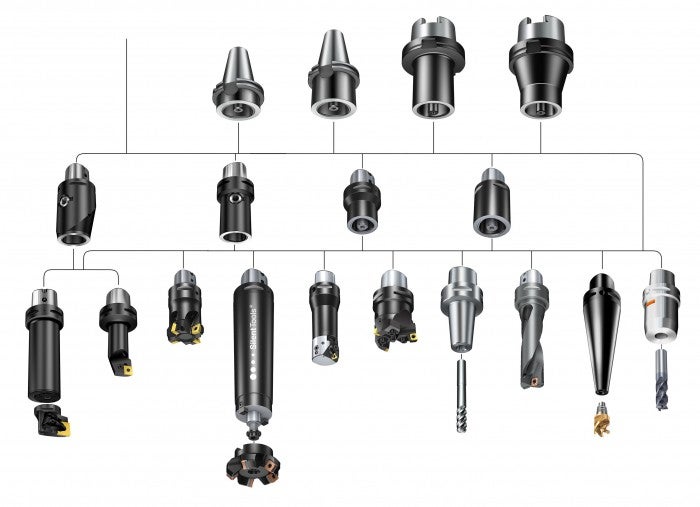

Modularity using Coromant Capto®

Using Coromant Capto® as an interface allows for a huge and flexible combination of assemblies for turning, milling, drilling, boring and tapping. This allows for a common tooling assortment with a relatively small inventory to cover all machine interfaces.

Coromant Capto® is used to build assemblies for:

- Machining centers – milling, drilling, boring and tapping

- Multi-task machines – turning, milling, drilling, boring and tapping

- Vertical lathes – turning

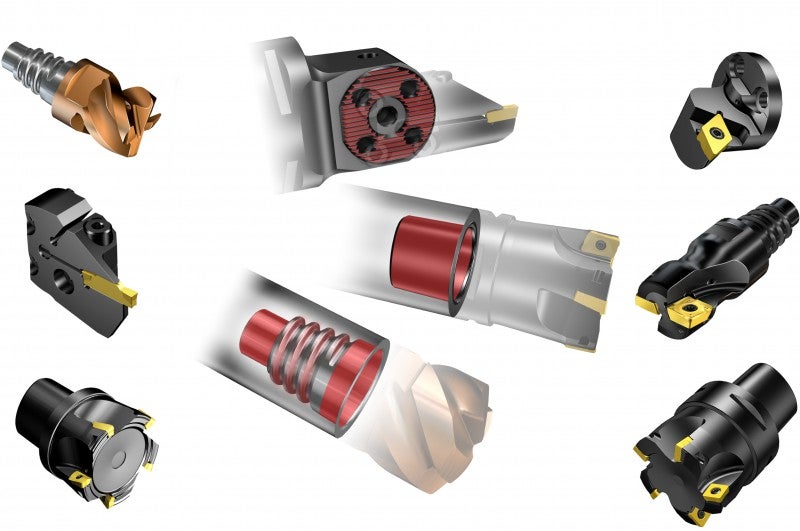

Modular tooling systems open up many flexible combinations of tool assemblies.

Machining center spindle interfaces can be divided into small/medium and large/extra-large.

Small and medium machine spindle interfaces are selected for smaller tool diameters and shorter gauge lengths, allowing for high rpms. For the best and most stable result, use the shortest assembly possible—preferably solid adapters.

Large and extra-large machine spindle interfaces are selected due to the requirement for stability for larger cutter diameters and longer assembly length.

| Steep taper (ISO/DIN, MAS-BT, CAT-V) | BIG-PLUS® (ISO/DIN, MAS-BT, CAT-V) | HSK-A | Coromant Capto® | |

| Small | 30 | 30 | 40, 50 | C4, C5 |

| Medium | 40 | 40 | 63 | C6 |

| Large | 50 | 50 | 100 | C8, C10 |

| Extra-large | 60 | 125, 160 | C10 |

The ability to tailor assembly lengths using extension and reduction adapters ensures maximum stability while at the same time eliminating the need for special adapters. All items are stocked as standard with next-day delivery, ensuring that inventory is kept low.

The machine interface adapters are available for all machine interfaces in two designs to be able to optimize the assembly length in combination with different lengths of extension/reduction adapters.

- Short/long length: Steep taper/BIG-PLUS®

- Slender/Heavy-duty: HSK

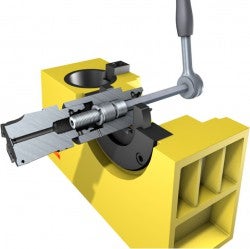

The center bolt assembly is easily carried out either at the machine or in a tool room using the fixture block.

Use a quick change adapter to dramatically reduce the time spent on set-up and tool change.

Modular solutions for turning applications

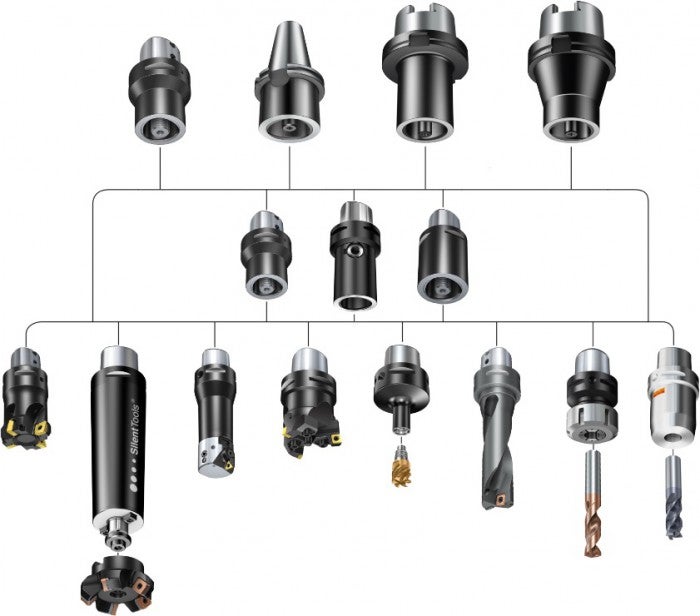

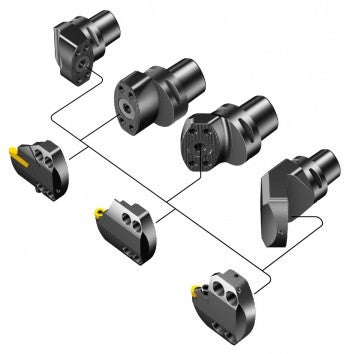

Modular solutions for turning, such as ®CoroTurn SL, provide great benefits for two main reasons: the ability to use different tool combinations and cost reduction.

Tool combinations: A wide range of combinations can be built up with a relatively small number of adapters and heads. This eliminates the need for most engineered tools and ensures that standard tools are always available, even for some special applications.

Cost reduction: Quick change holders are more expensive than a shank tool or boring bar. Using modular solutions for turning in some of the higher-risk applications helps to keep the tool cost at the same level as it is for shank tools in the long run.

Modular solutions are available for both internal and external turning, parting, grooving and threading applications.

With modular tooling systems you can build many combinations with a small number of adapters and heads.

There are also modular options for multi-task machining, which is beneficial when there is a need to reduce tool change time and at the same time rationalize the number of magazine pockets by using multiple cutting heads on one adapter.

Typical situations where modular solutions are beneficial:

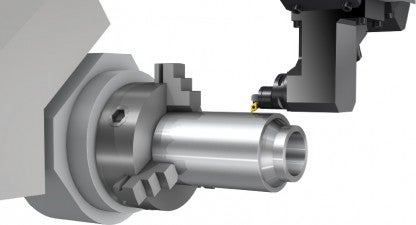

- Profiling and grooving on large diameter components. Clearance is applied to the cutting heads, as well as internal machining, so each cutting head can be used in any configuration. CoroTurn® SL oval coupling SL70 is a robust solution that gives the rigidity and accessibility needed

- External turning applications where Coromant Capto® cutting units are not available, such as when there is need for extra clearance on RAMs for vertical lathes and when using internal clamping units

Modular solutions for small/medium-sized machines

Milling and boring assemblies require the flexibility to optimize gauge lengths to the features being machined to minimize the risk of vibration. Critical gauge length, stick-out length and clearance/overhang are the main assembly categories requiring consideration.

Critical gauge length

When machining over 3 times the spindle contact diameter, vibration will become a problem, with higher cutting forces limiting the metal cutting efficiency. A spindle interface with flange contact (BIG-PLUS® and HSK), provides increased stability and productivity. The gauge length is a limiting factor on small and even medium-sized, interfaces for end mills.

Stick-out length

The stick-out length from the chuck has an impact on stability, and therefore the tendency to vibrate. 4 x D is the absolute limit for steel shank tools. Over 4 x D solid carbide or heavy metal shanks are required to be able to run without vibration.

Clearance/overhang

Even in small/medium-sized machines it could be of interest to use a longer tool assembly to reach the area to be machined. In this case, it is important to think about clearance for the whole assembly. Use either an oversized cutter with a straight adapter (a) or an undersized shank with nominal cutter (b). For more details, see Long overhangs – Considerations

a

b

Learn about Coromant EH, a modular solution for small diameters that provides a broad range of heads and adapters.

Grooving solutions

Groove machining on power components requires versatile, rigid tools suitable for... chevron_right

Quick change solutions

Productivity factors Productivity is the number of parts produced per shift or week.... chevron_right

Mandrel

A mandrel is a bar, shaft or spindle around which other components are arranged or... chevron_right

Thrust fittings

The thrust fitting is normally produced in titanium and is located between the wing... chevron_right