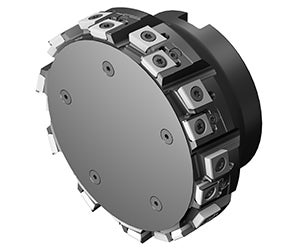

M5Q90 – for first stage roughing operations

M5Q90 is a new concept roughing tangential milling cutter. It is designed to clean surfaces in the first machining stage of newly cast aluminium parts in a single operation without burring.

PCD tangential inserts provide a smooth cutting action, which lowers power consumption and eliminates vibration. This ensures a reliable performance, improved tool life and increased number of components machined per insert.

Features and benefits

- Excellent tool life and surface quality

- Tangential insert position for better stability

- Dedicated PCD insert geometries

- Positive cutting angle to reduce cutting efforts

- Rotating prevention system with anti-ejection

- Precision coolant channels designed for emulsion and MQL

- One tip seat design used for all engineered tools

- Easy to clamp (screw clamping) and easy to set

- Inserts and spare parts in stock

- Reduced burr formation

- Able to machine in high speed conditions (over 20000 rpm)

Application

- Cubing, first stage, roughing operations

- Depth of cut with PCD insert in full engagement 2–4 mm (0.079–0.157 inch)

- Greater depth of cut can be obtained by using protective rows containing carbide inserts

- Face and shoulder milling

- Aluminium cylinder head, engine block, component first machining or stage after casting