How to choose infeed method in thread turning operations

OptiThreading™

What is OptiThreading™?

OptiThreading™ is a method with tool oscillation movements that will enable controlled chip breaking in thread turning applications. This unique method gives repeated interrupted cuts on all passes except the last one.

OptiThreading™ advantages

- Less manual work removing long chips jamming the tool, the component and or the chip conveyor

- Less unpIanned machine stops for higher productivity and better automation

- Increased component surface quality as no long chips will damage the component

- It gives a thread with increased surface finish and controlled vibrations

- Possibility to increase cutting speed mainly for bigger threads/diameters which results in higher productivity

- Less vibrations due to method – possibility to increase tool overhang

What to consider with OptiThreading™

- For CNC machines that can handle ISO code (G32/G33/G34)

- External and internal applications

- Normal and conical/tapered threads

- For all standard thread types above a thread diameter of 12mm

- Recommended to run with coolant

How to apply Optithreading™

Watch the video on how to generate an NC program with CoroPlus® Tool Path software.

Conventional thread turning methods

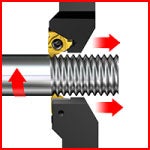

There are three main thread turning infeed methods; modified flank infeed, radial infeed and incremental infeed. The infeed method dictates how the insert is applied to the workpiece to create the thread form.

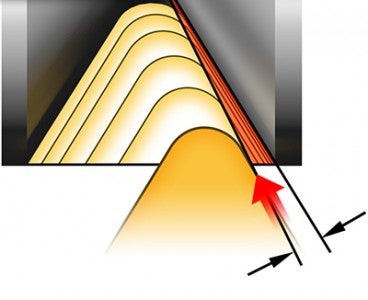

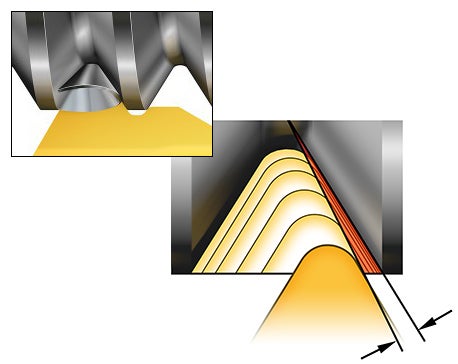

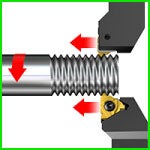

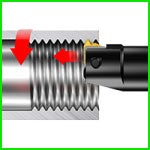

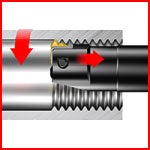

Modified flank infeed

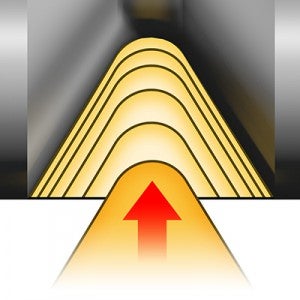

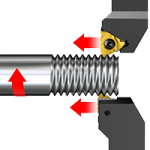

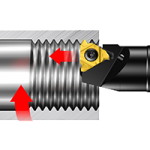

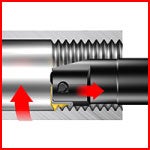

Radial infeed (straight infeed)

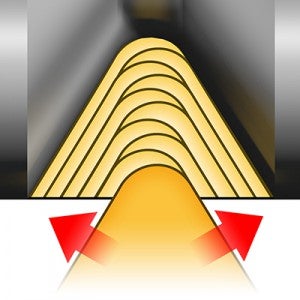

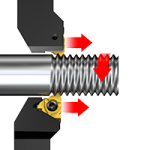

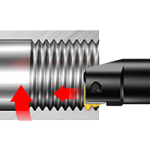

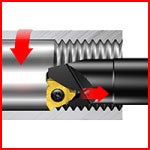

Incremental infeed

The choice of infeed method is influenced by the machine tool, insert geometry, workpiece material, thread profile and pitch and will directly influence:

- Chip control

- Thread quality

- Insert wear type

- Tool life

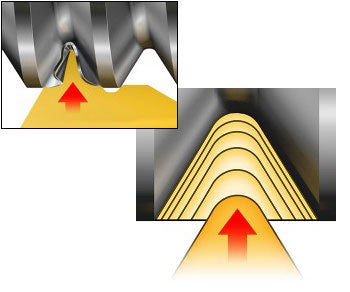

Modified flank infeed

Modified flank infeed is the first choice method, giving the longest tool life and best chip control. Most CNC machines are pre-programmed for this method which is slightly modified (angled) to avoid the insert edge rubbing on the component surface.

- Recommended for all thread turning operations and insert types

- Chip is thicker but generated only on one side of the insert, making it easier to cut

- Fewer passes needed as less heat is transferred to the insert

- Can be used on both flanks of the thread (opposite flanking) to steer the chip in best direction

- Used for larger threads and to eliminate vibration problems

- For inserts with chip-breaking geometry, this is the best suited infeed method, an infeed angle of 1° should be used

Machine code examples:

G76, X48.0, Z-30.0, B57 (Infeed angle), D05 etc.

For different machine types, the parameter for flank infeed can be: G92, G76, G71, G33 and G32

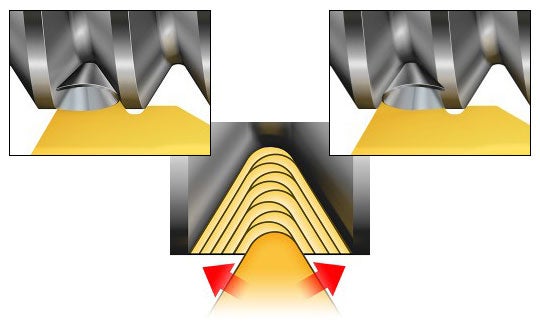

Radial infeed

Radial (straight) infeed is the most commonly used infeed method and the only possible on many non-CNC lathes.

- Produces a stiff, V-shaped chip, which is difficult to form and control

- Insert wear is even on both flanks

- Suitable for fine pitches

- Insert tip is exposed to high temperatures, restricting the possible infeed depth

- Risk of vibration and poor chip control in large pitches

- Chip-breaking geometries are not suitable for radial infeed.

Incremental infeed

Incremental infeed is the first choice for larger thread profiles (recommended for pitches larger than 5 mm (5 t.p.i)).

- Chips are directed both ways, making chip control difficult

- Gives an even insert wear and the longest tool life in very coarse threads

- Any geometry can be used for incremental infeed

- Requires a special CNC machine program

Depth per pass

Infeed recommendations can be found in the catalogue or in ToolGuide. Those are recommended as starting values and the most suitable number of passes must be tried out for the specific thread turning operation.

- Infeed less than 0.05 mm (0.002 inch) should be avoided

- For Cubic Boron Nitride-tipped inserts, infeed should not exceed 0.10 mm (0.004 inch)

- For multi-point inserts, it is essential that the correct infeed recommendations are used

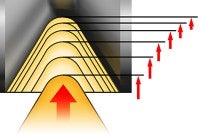

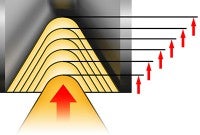

Decreasing depth per pass (constant chip area)

Decreasing infeed depth per pass is the most common way to improve the machining result, and is the first choice for all thread turning operations.

- Keep the first pass the deepest and the last pass around 0.07 mm (0.003 inch)

- Gives an even load on the insert and a more “balanced” chip area

Constant depth per pass

With a constant depth per pass, each pass (except the last) is of equal depth, regardless of number of passes. This is a less productive method.

- Increases the required number of passes

- More demanding on the insert

- Can offer better chip control

- Should not be used for pitches larger than 1.5 mm or 16 t.p.i.

Thread turning cycles on CNC lathes

Standard CNC lathes have dedicated thread turning cycles, where pitch, thread depth and number of passes can be set in different ways – including the first and last pass.

For the last pass, we strongly recommend against using a spring pass (where the cutting depth of the last pass equals the cutting depth of the pass before). It is more beneficial to use the recommended infeed cycles to ensure good thread quality and long insert tool life.

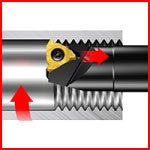

Tool feed direction

A thread can be produced in a number of ways. The spindle can rotate clockwise or counter clockwise, with the tool fed towards or away from the chuck. The thread turning tool can also be used in normal or upside-down position (the latter helps to remove chips).

The most common set-ups is marked with green in the figure below.

Working away from the chuck (pull threading)

Using right-hand tools for left-hand threads (and vice-versa) enables cost savings through tool inventory reduction.

A negative shim must be used in set-ups marked with red in the figure below.

| External | |

| Right hand threads | Left hand threads |

Right hand tool/insert |  Left hand tool/insert |

Right hand tool/insert |  Left hand tool/insert |

Left hand tool/insert |  Right hand tool/insert |

| Internal | |

| Right hand threads | Left hand threads |

Right hand tool/insert |  Left hand tool/insert |

Right hand tool/insert |  Left hand tool/insert |

Left hand tool/insert |  Right hand tool/insert |

Left hand tool/insert |  Right hand tool/insert |