What is thread milling?

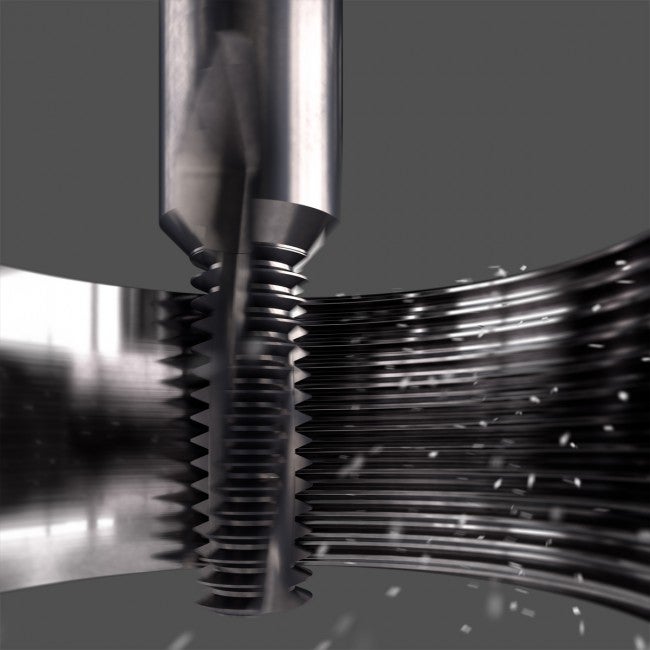

Thread milling produces threads with the circular ramping movement of a rotating tool. The lateral movement of the tool in one revolution creates the thread pitch.

Although not as widely used as thread turning, thread milling achieves high productivity in certain applications.

Thread milling should always be the application of choice when:

- Machining asymmetric/non-rotating components

- Machining materials that cause chip breaking and chip evacuation problems

- Machining tough materials that create high cutting forces

- Machining against a shoulder or close to the bottom of a blind hole

- Machining thin-walled components

- Component set-ups are unstable

- Tool inventory needs to be minimized

- You do not want to risk tap breakage on expensive parts – thread mills can always be removed from the component completely

- A machine tool capable of simultaneous movement in the X, Y and Z-axis directions is required

For more information about thread milling please see our Application guide

High-precision Thread Whirling with CoroMill 325

open_in_new

CoroMill® Plura Insights Broadcast: Episode 5 - End milling with long overhangs

In this broadcast series we take a look at how to use CoroPlus® Toolguide to get... open_in_new

CoroMill® Plura Insights Broadcast: Episode 6 - Influence of the spindle speed

In this broadcast series we take a look at how to use CoroPlus® Toolguide to get... open_in_new