Milling programming

Centre line or periphery feed

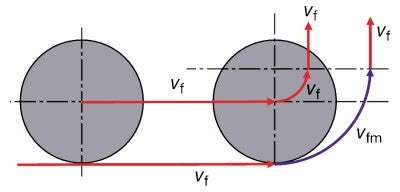

A machine is designed for either centre line feed, vf, (without radius compensation) or periphery feed, vfm (with radius compensation).

If the machine requires a centre line feed, and periphery feed is programmed instead (on machines without radius compensation), the fz value will become too high, with the subsequent risk of insert breakdown.

Centre line, vf, or periphery feed, vfm.

Centre line feed programming

The NC codes generated will program the centre of the cutter rather than the periphery.

For straight line cutting (G1), the feed at the wall of the component, vfm, is the same as the programmed feed, vf, while the periphery feed around a radius (G2) will be higher than the tool centre feed. Therefore the table feed, vf, needs to be reduced to maintain the feed per tooth, fz.

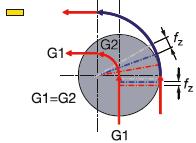

Without centre line feed reduction,

fz will increase in corners.

With centre line feed reduction.

Centre line feed reduction

A reduction factor is found in the table, and is dependent on:

- Cutting diameter to component radius – DC/radm

- Radial immersion – ae/DC

| kReduction factor value for feed in corners () | ||||||||||

| DC/radm | ae/DC | |||||||||

| 0.05 | 0.15 | 0.25 | 0.35 | 0.45 | 0.55 | 0.65 | 0.75 | 0.85 | 0.95 | |

| 2.00 | 0.22 | 0.34 | 0.40 | 0.45 | 0.48 | 0.53 | 0.60 | 0.67 | 0.75 | 0.86 |

| 1.80 | 0.30 | 0.34 | 0.42 | 0.46 | 0.50 | 0.53 | 0.60 | 0.67 | 0.75 | 0.86 |

| 1.60 | 0.44 | 0.42 | 0.44 | 0.49 | 0.53 | 0.56 | 0.60 | 0.67 | 0.75 | 0.86 |

| 1.40 | 0.55 | 0.54 | 0.54 | 0.54 | 0.56 | 0.59 | 0.62 | 0.67 | 0.75 | 0.86 |

| 1.20 | 0.63 | 0.64 | 0.64 | 0.62 | 0.62 | 0.65 | 0.63 | 0.71 | 0.75 | 0.86 |

| 1.00 | 0.71 | 0.72 | 0.72 | 0.73 | 0.74 | 0.62 | 0.77 | 0.79 | 0.83 | 0.86 |

| 0.80 | 0.78 | 0.79 | 0.79 | 0.80 | 0.82 | 0.83 | 0.85 | 0.87 | 0.89 | 0.94 |

| 0.60 | 0.84 | 0.85 | 0.86 | 0.86 | 0.87 | 0.88 | 0.90 | 0.91 | 0.93 | 0.96 |

| 0.40 | 0.90 | 0.90 | 0.91 | 0.92 | 0.92 | 0.93 | 0.94 | 0.95 | 0.96 | 0.98 |

| 0.20 | 0.95 | 0.96 | 0.96 | 0.96 | 0.96 | 0.97 | 0.97 | 0.98 | 0.98 | 0.99 |

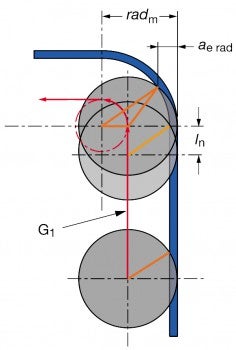

Feed reduction prior to corner

Reducing the feed before reaching the corner is especially essential when milling at high speeds.

As the cutter is still feeding straight towards the end of the G1 line, the arc of engagement starts to increase. Therefore, the feed has to be reduced before the corner is reached, i.e. within the ln range that is 50% x DC.

A machine control with an advanced look-ahead function will manage the changes in feed rate automatically.

Reduce the feed at a distance:

ln = 50% DC

Tips film: Cam programming

Understand the influence that CAM programmers have regarding: machining strategy,... open_in_new

Tips film: Ceramic milling in super alloy materials

Explore the advantages with ceramic milling and the importance of optimized programming... open_in_new

Tool and cutting data recommendation with CoroPlus ToolGuide

Get a tool recommendation including speeds and feeds based on the task that you are... open_in_new

Optimize your tool path with CoroPlus® ToolPath for PrimeTurning™

Optimize your tool path with CoroPlus® ToolPath for PrimeTurning™ open_in_new