PrimeTurning™ in ISO S

ISO S materials, for example, titanium, Inconel 718 and other Inconel-cladded materials, are common for oil, gas and aerospace components. With the possibility to use a one-pass strategy, the PrimeTurning™ methodology and CoroTurn® Prime tools are highly productive solutions when machining in ISO S, both for internal and external turning.

Typical components for which PrimeTurning™ can be a good choice are the tubing hanger, spool body and engine shaft.

Features and benefits

- Higher cutting data allows for increased component output and reduced cost per component

- Lower cutting edge temperature helps improve tool life

- Consistent tool life leads to improved machine utilization, fewer tool changes and reduced costs

- Good chip control and long tool life increases process security, which means fewer machine stoppages

- Wiper insert available for excellent surface finish

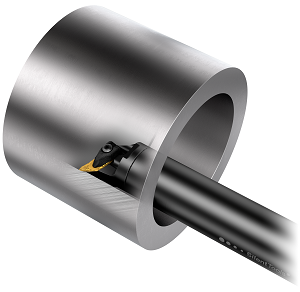

Internal turning with CoroTurn® Prime SL head

- For diameters above 40 mm (1.575 inch) and overhangs up to 8–10 × D

- Excellent chip evacuation and chip control – when machining in the inside-out direction, chips are easily evacuated from the hole

- Vibration-free internal machining in combination with Silent Tools™ dampened boring bars

External turning with CoroTurn® Prime

- Best suited for short and compact components and slender components using tail stock

- Coromant Capto®, shank and QS™ system

- Use the PrimeTurning™ code generator to correctly program codes and techniques