Solutions for cost-effective and high-quality machining of oil and gas API seal ring grooves

Seal ring grooves are critical features on many oil and gas components and require close tolerances and a high-quality surface finish. The high component value and complexity make process security essential. Commonly used materials are solid Inconel 718 and cladded Inconel 625, which are difficult to machine and add to the challenges.

Tooling solutions for machining of oil and gas – API seal ring grooves features

Machining challenges

Many conventional methods for machining seal ring grooves have poor process security and slow down production. Conventional plunging and radial turning tools need to perform roughing and finishing in multiple operations. Such high cutting forces limit tool life. When these processes are secure, they are slow and costly with no flexibility regarding groove diameter.

SpiroGrooving™

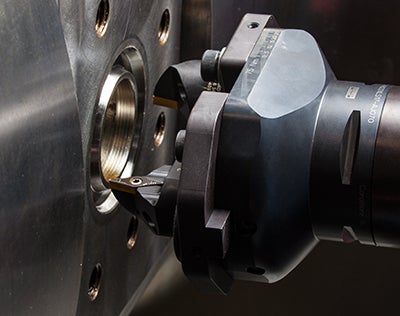

SpiroGrooving™ is a simple yet sophisticated manufacturing process for grooves on sealing rings. The method is used with the CoroBore® XL system and utilizes a spirograph tool path to create close-tolerance seal ring grooves in a very secure and productive manner.

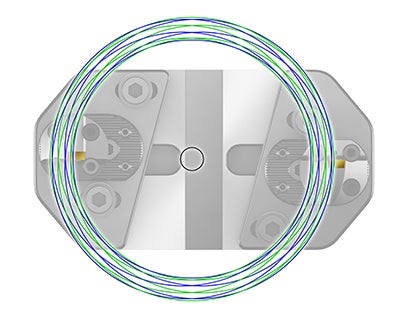

The tool path consists of tapered, circular ramping where tool engagement is set according to a ramping pitch for each revolution. An NC code generator calculates the SpiroGrooving™ tool path based on a few input parameters, such as groove diameter, process pitch and the chosen maximum chip thickness. Tool presetting is done in a few simple steps.

This solution is ideal for making seal ring grooves in pre-clad machining of steel and stainless steel. The unique internal coolant solution of CoroBore® XL facilitates machining in advanced materials. Roughing and finishing are carried out in the same operation, which significantly reduces machining time and improves productivity.

Main benefits

SpiroGrooving™ fulfills all the crucial objectives for machining seal ring grooves in the most efficient and reliable manner:

- Considerably reduced cutting time through higher cutting data

- Very high process security

- Wide application flexibility with minimized tool inventory

- Quick and easy programming with the unique NC code generator tool and spindle.

Spirograph

SpiroGrooving™ uses a circular spirograph tool movement in a taper. This reduces chip thickness, enabling light cutting action and increased feed. Parts of the insert cutting edge demonstrate interrupted cutting behavior, eliminating long chips that tangle with the tool and spindle.

Tooling components

The tooling is based on state-of-the-art, proven, standard concepts, where modularity provides broad groove-application flexibility. Where conventional methods require a new set of tools for every groove type or size, one SpiroGrooving™ tool covers a range of diameters, providing flexibility in production and a minimized tool inventory.

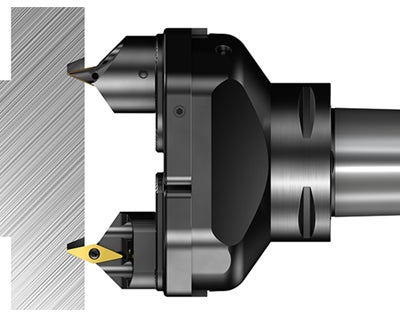

The tool for SpiroGrooving™ is an uncomplicated, clever, twin-edge tool with two V-style inserts based on the well-established CoroBore® XL boring system. When combined with the Coromant Capto® modular tooling concept, it offers a dedicated solution for seal ring groove machining

SpiroGrooving™ with CoroBore® XL

| Component features | BX-154 grooves in a steel valve body Diameter: 101 mm (3.99 inch) Groove width: 15.4 mm (0.606 inch) Depth: 7.5 mm (0.297 inch) | |||||

| vc | n | Roughing vf | Finishing vf | ap | Total time | |

| Competitor seal ring groove solution | 187 m/min (614 ft/min) | 500 rpm | 100 mm/min (4 in/min) | 50 mm/min (2 in/min) | 1 mm/cycle (0.04 inch) | 2 min |

| vc | n | Roughing vf | Finishing vf | Pitch | Total time | |

| SpiroGrooving™ with CoroBore® XL | 300 m/min (984 ft/min) | 922 rpm | 392 mm/min (15 in/min) | 50 mm/min (2 in/min) | 2 mm/rev | 50 sec |

With the conventional radial, multi-edge turning concept for roughing and finishing operations, the total machining time was two minutes. No diameter flexibility was available and setting involved a relatively lengthy procedure.

After switching to SpiroGrooving™, machining time was reduced to 50 seconds. The tool can be used and easily reset for several other groove applications. The component was finished in less than half the time with the new method.

58%

SHORTER

MACHINING

TIME

Tips film – machining of API seal ring grooves

Tips film - #35 Machining of API seal ring grooves

Learn how to handle challenges when machining API seal ring grooves. The SpiroGroovingâ™... open_in_new

SpiroGrooving

Innovative solution for machining of API seal ring grooves open_in_new

Training Handbook

B • Use the insert width to produce full <code>grooves</code> and then remove the... chevron_right

Tools for sliding head machines 2019

Good for widening of <code>grooves</code>. ... Generates flat bottom <code>grooves</code>.... chevron_right