CoroTurn® Prime

All-directional turning

Extraordinary productivity for internal turning applications

With the CoroTurn® Prime SL head solution, it is possible to use our PrimeTurning™ methodology for internal turning. The inside-out machining capability allows for excellent chip evacuation and chip control.

Second-generation B-type inserts

CoroTurn® Prime B-type now includes double-sided negative inserts with four cutting edges for cost-efficient machining. The tool also features a new robust tip seat design and updated geometries which are particularly suitable for challenging materials.

Y-axis turning

Y-axis turning is a 3-axis simultaneous turning method in which the tool rotates around its own center. The insert machines in the Y-Z plane and the milling spindle axis interpolates during turning. This allows several complex features to be machined with a single tool.

Application area

Turning operations in all directions

- CoroTurn® Prime A-type tool with three 35° corners designed for light roughing, finishing and profiling

- CoroTurn® Prime B-type tool with double-sided negative inserts with four cutting edges, designed for finishing and roughing

- Machines: Turning centers, vertical lathes and multi-task machines

- Good choice for mass production or components needing frequent set-ups and tool changes

- External turning: Best suited for short and compact components and slender components using a tailstock

- Internal turning: For diameters above 40 mm (1.575 inches) and overhangs up to 8–10 × D

Product range

Coromant Capto®

Tool holders

Radial holders, size: C3, C4, C5 and C6

Axial holders, size: C5 and C6

Multitask holders, size: C5, C6 and C8, HSK63-T

Multitask Twin-tool holders, size: C6 and C8

QS™ shanks

Sizes: 2020, 2525 mm, 12 and 16 ( and 1 inch)

Shank

Sizes: 2020, 2525, 3232 mm, 12, 16 and 20 (, 1 and 1 inch)

CoroTurn® SL head

Size: SL32 and SL40

Y-axis turning

Tool holder: Coromant Capto® C6

Master insert: CP-A1108

A-type insert

Grades: GC4425, GC4415, GC2025, GC1210, GC1115 and H13A

Geometries: -L5, -L5W, -L3, and -L3WX

Insert shape: 35° corner (KAPR 30°)

B-type insert

Grades: GC4425, GC4415, GC2220, GC2025, GC1210, GC1115, S205 and H13A

Geometries: -M5, -M5W, -M7, -M7W, -L4 and -L4W

Insert shape: Tip shaped as CNMG (KAPR 25°)

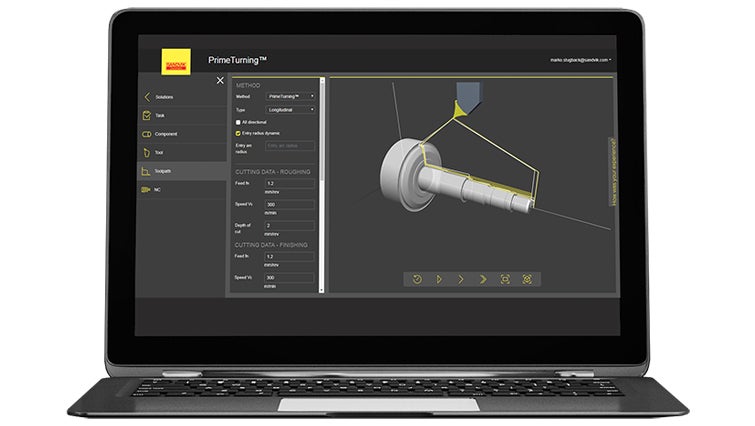

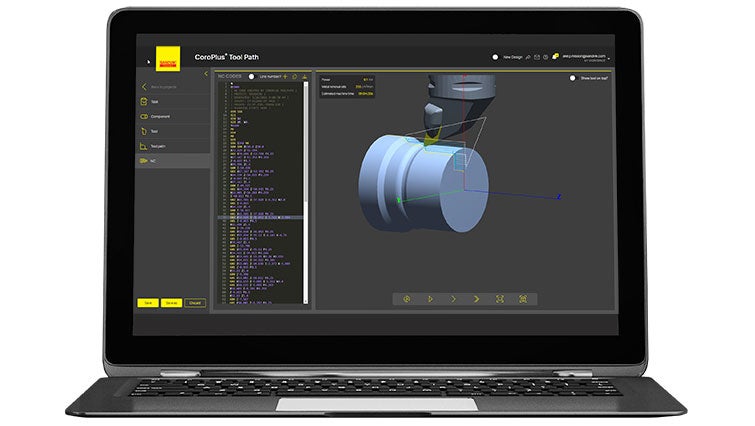

CoroPlus® Tool Path for PrimeTurning™

Ingeniously designed software generating correct and optimized NC codes to speed up turning operations, supported by our CAM partners.

CoroPlus® Tool Path software

The CoroPlus® Tool Path software supplies programming codes and techniques to ensure maximum output for PrimeTurning™ applications. It is compatible with various CNC machines that use ISO codes. Learn more

Highlights

All-directional Y-axis turning

Do you want to learn more about how to machine a complex component with a single turning tool? Find out why Y-axis turning has the potential to substantially advance your production.

Increase output in steel turning

Steel turning often means continuously refining your machining processes. Small improvements in your turning strategy can make a big difference. Explore new technologies and methods that can give you an edge over the competition.

Now it's your turn

Challenging situations require smart solutions. When faced with full order books but a shortage of skilled workers, BHDT, the Austrian specialist in high-pressure systems and components for the chemical and petrochemical industry, looked into how new, innovative technologies could support them. By applying PrimeTurning, they were able to reduce the machining time by 50 percent.

Join us. Stay updated.

Sign up for our newsletter today