Tooling solutions for machining gear wheels

Gears come in many different shapes and forms they transform the vehicle power into different speeds and torques.

Soft turning and gear milling are performed before the case hardening process, where the challenge is often to acquire close dimensional tolerances. Careful preparations for the hardened stage provide a relatively straight-forward hard part turning operation. In hard part turning, predictable machining and good surface finishing is essential. All this goes together with cost-effectiveness.

Besides our extensive standard offer, Sandvik Coromant also has dedicated products and engineered solutions that provide full support to overcome the challenges presented by manufacturing these components.

Tooling solutions that support manufacturing gear wheels:

ISO P offer – Turning inserts and grades for steel

Whether you are looking for turning insert grades for unmanned production or custom-made components, we have reliable insert grades that offer a predictable tool life, high machine utilization, and the surface quality you need.

CoroTurn® Prime – All-directional turning

Double the speed and feed rates compared to conventional turning, and with longer tool life.

CoroTurn® 300 – Effective and high-quality turning

High-precision coolant from above controls the chip breaking for secure machining, while under coolant controls the temperature for long and predictable tool life. Eight-edged inserts.

ISO H offer – Turning inserts and grades for hardened steel

Turning hardened steel calls for super-hard insert grades. Whatever your component or requirements for surface finish, find productive insert grades here that can withstand high temperatures and cutting forces and still retain their cutting edges.

Xcel – CBN grade for optimal finish quality

Up to eight cutting edges, shorter production times, and considerably reduced tool costs per component.

High-pressure coolant

Sandvik Coromant has developed high-pressure coolant solutions that can help reap benefits in terms of increased tool life, improved component consistency and greater process security.

More about the benefits of high-pressure coolant

Power skiving

- CoroMill® 178 – PM-HSS and solid carbide power skiving tools for gear and spline production with high output.

- CoroMill® 180 – Indexable two-edge power skiving cutters for gear and spline production with high output.

Explore more about power skiving – productivity in mass production

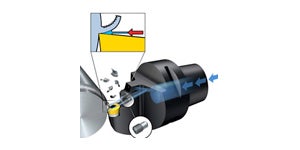

Deburring

M670 is a high-precision deburring solution for internal and external machining of straight profile gears and splines.

It is possible to use M670 together with the CoroMill® 180 power skiving concept in a synchronized set-up in a multitask machine.

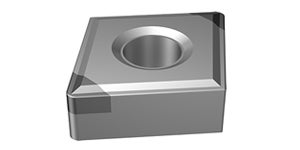

CBN insert with integral chip breaker

This CBN insert is for hard-to-soft rough machining automotive components, such as gears, crown wheels, shafts, and all case-hardened components where the hardened layer needs to be removed.

* For engineered tooling solutions, please contact your local Sandvik Coromant sales representative.