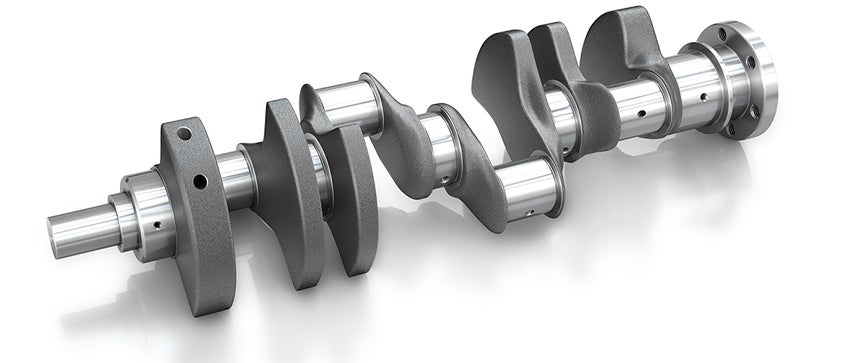

Crankshafts

The asymmetrical, long and relatively slender crankshaft constitutes the heart of any combustion engine, from two-wheelers to heavy trucks. It is also one of the most challenging components to machine. The design, in combination with high tolerance demands and the challenging machinability of the material, forged steel or nodular cast iron, requires truly optimized tools and methods for success.

Solutions and tools for machining crankshafts

Crankshaft solutions

Dedicated engineered and standard solutions for productive and efficient crankshaft machining.

More about Crankshaft solutions

CoroDrill® 865 – Oil hole drill

Stable drilling of oil holes up to 25 times the cutting diameter. CoroDrill 865 offers high penetration rates, repeatability and process security.

Read more

CoroDrill® 860 – Optimized multi-material drilling solution

CoroDrill® 860 with -GM geometry is a high-performance drilling solution for short holes, primarily in ISO P, M, K and H materials. It performs competitively in ISO N and ISO S materials as well. The drill offers robust process security, high hole integrity and excellent tool life

Read more about CoroDrill® 860

CoroChuck® 930 – High-precision hydraulic chuck with high pull-out security and precision

With the best pull-out security on the market, this chuck is designed to eliminate vibration for excellent stability and accessibility in all milling and drilling operations.

Read more

CoroTurn® Prime – All-directional turning

Double the speed and feed rates compared to conventional turning, with longer tool life.

M642 and M632

M642 (internal milling) and M632 (external milling) are a new crankshaft disc milling... chevron_right

Crankshaft solutions

Sandvik Coromant has an extensive and complete offering for crankshaft machining,... chevron_right

CoroDrill® 861

CoroDrill 861 provides the high stability essential for drilling deep holes, with... chevron_right

Cam shaft

In an internal combustion engine, the camshaft is used to operate valve movement... chevron_right