Tooling solutions for machining camshafts

In an internal combustion engine, the camshaft is used to operate valve movement and synchronization. It consists of a shaft with several lobes, one for each valve. The cam lobes force the valves to open by pressing on them (or on some intermediate mechanism) as they rotate.

Sandvik Coromant has a competitive range of standard and Tailor Made solutions for camshaft machining as well as Engineered solutions as shown below.

Camshaft milling tools

The requirements on camshafts are following the same trends as for crankshafts; focusing on performance, lower fuel consumption, and fewer emissions. For the best performance, use a camshaft milling solution that allows for the simultaneous machining of several cams. All cutters can be delivered in solid versions or as a segment solution. Inserts with well-tuned grades, optimized geometries, and up to eight cutting edges result in safe production and low production costs.

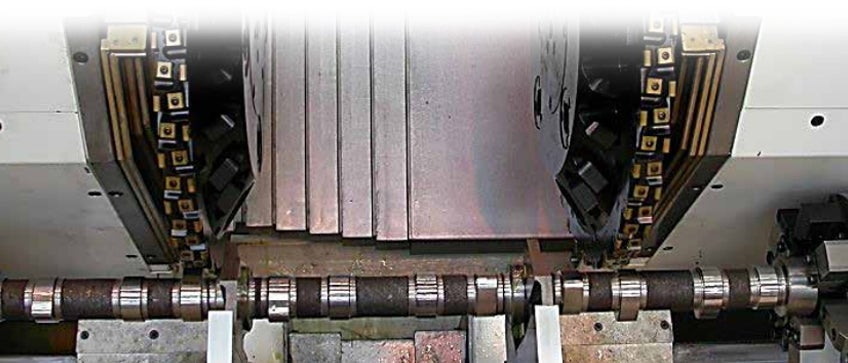

M631 camshaft milling tools

Camshaft milling tools (external milling)

- Diameters from 300–500 mm (11.81–19.68 inches)

- Various widths

- Solid disc or segment solution

- Variety of segment mountings

- Various couplings for different machine tool makers

- Simultaneous machining of several cams

- Tandem cutters

* For Engineered tooling solutions, please contact your local Sandvik Coromant sales representative.

Future trends in aerospace

For decades, aerospace has been an industry characterized by growth. There have been... chevron_right

A greener future for aerospace

OEMs must take a holistic approach to tomorrow’s aircraft. As one of the largest... chevron_right

Improving Process Security for Machining HRSA Aerospace Engine Components

This isn't easy, especially for machine shops seeking to add HRSA capabilities.... chevron_right

CoroPlex® YT

Significantly reduced tool change time Evenly distributed insert wear increases... chevron_right