CoroTurn® 300

Effective and high-quality turning

Chip control and long and predictable tool life

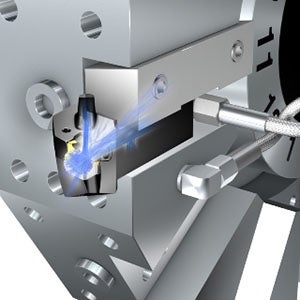

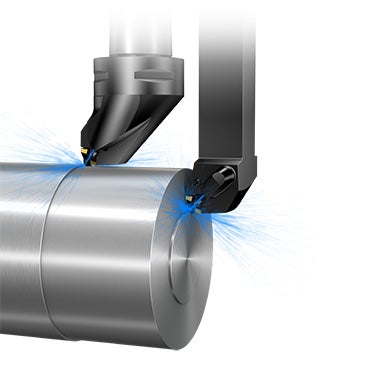

High precision coolant from above controls chip breaking for secure machining, while under coolant controls the temperature for long and predictable tool life. The coolant also has positive effects on the surface quality.

High-quality surfaces

To achieve the highest surface quality, the key is to prevent cutting forces from causing micro-movements of the insert. iLock®, an interface between the insert and the holder, has been developed to meet this challenge.

Easy tool change for maximized production time

Coromant Capto® interface or QS™ shanks enable quick tool change and easy coolant connection for maximized production time.

Application area

External operations

- Longitudinal and face turning

- Finishing to medium

- Machine types: turning centers and multi-task machines

Product range

Coromant Capto®

Tool holder sizes: C4, C5, C6

QS™ shanks

Sizes: 2020, 2525, 12 (3/4"), 16 (1")

Coromant Capto® for multi-task machines

Tool holder sizes: C5, C6

Eight-edged inserts

Grades: GC4425, GC4415 Geometries: -L4, -M5, -M5W Insert shape: 80 degree corner

Eight-edged smartness

The eight-edged inserts in CoroTurn® 300 ensure good heat transformation for predictable performance and wear. More edges also means fewer inserts, which in turn means better control of the inventory. The geometries are designed for excellent chip breaking within their respective application areas. Last but not least, the eight-edged inserts are designed with less carbide per edge, so there is less material to recycle or waste. That’s good for your business and for the environment.

Highlights

Demo: Turning with CoroTurn® 300

See CoroTurn® 300 in face and longitudinal turning operations and the result after using all eight edges.

New generation steel turning grades

Steel turning often means continuously refining your machining strategy. The new all-black CoroTurn® 300 inserts in grade GC4425 and GC4415 offer substantially increased edge-line security. The unique combination of wear resistance and toughness take performance to a new level.

Get to know CoroTurn® 300

See how to change inserts, connect coolant, and other valuable things about CoroTurn® 300 in this animation.

Amazingly safe, amazingly versatile

CoroCut® 1-2, the number one versatile parting and grooving concept on the market, has been upgraded. View all the new features CoroCut® 2 has to offer.

Animation: QS™ Micro

Watch the unparalleled precision and modularity of the QS™ Micro quick-change solution

Application checklist and hints

What should you consider when performing a shoulder milling operation? Find useful tips and tricks here.

Join us. Stay updated.

Sign up for our newsletter today