Milling inserts and grades for steel

Find your CVD- and PVD-coated carbide grades and uncoated cermets optimized for steel.

GC4330 and GC4340

Grades GC4330 and GC4340 are CVD grades optimized for steel milling, offering substantially increased tool life and improved process security. GC4330 is the first choice for roughing to semi-finish face milling, while GC4340 is the first choice for rough shoulder milling and groove milling. Grade GC1230 is optimized for light roughing to finishing operations in steel milling. It covers general applications to challenging applications such as square shoulder, complex tool paths and deep cavities. This grade excels in both edge line toughness and wear resistance, allowing you to opt for a longer tool life or higher productivity, or to machine with a more sustainable approach.Technical features

Benefits

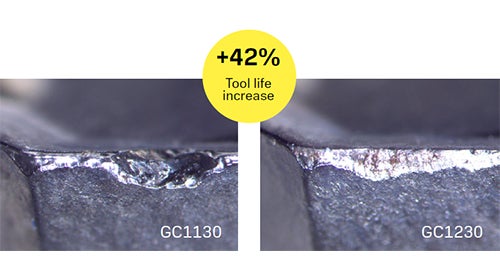

GC1230

Features and benefits

Steel milling with GC4330 and GC4340

Inveio® technology features tightly-packed unidirectional crystals, which create a strong barrier towards the cutting zone for maximum thermal protection. This has a significant effect on insert strength, wear resistance and tool life.

Optimized for steel milling

Produced with Zertivo™, a unique PVD production technology, GC1230 increases the predictability and security of your milling process.

Performance Results

Learn how the enhanced properties of GC1230 outperforms other grades in customer workshops.

Steel Milling Grade GC1230

Get an in-depth look at the many uses of GC1230.

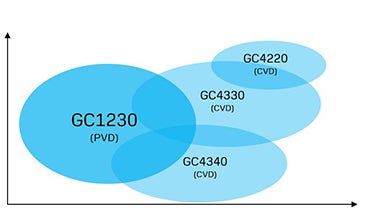

Find your grade

Our steel insert grade assortment consists of CVD- and PVD-coated carbide grades and uncoated cermets for various machining conditions.

Stable conditions Unstable conditions |  |

Low heat High heat (Small cutters (Large cutters |

GC1230

Nano multi-layer PVD-coated grade produced with Zertivo® technology. Designed for light roughing to finishing operations, both for wet and dry machining. Good choice for complex tool paths and sticky materials.

GC1130

Hard, thin coated PVD-grade with Zertivo® technology for various applications. Suitable from light roughing to finishing in average stability for wet and dry machining. Good choice for complex tool paths and sticky materials.

GC4330

Medium hard CVD-coated grade (medium to thick coating) designed for medium to rough milling applications in average cutting conditions for wet and dry machining.

GC4340

Tough CVD-coated grade (medium thick coating) suited for tough and demanding medium to rough milling applications for wet and dry machining.

GC4220

Hard, CVD-coated (thick coating) grade suitable for high cutting speeds in medium to rough milling application with good stability for dry machining.

Complementary grades

Highlights

Milling power unleashed

Explore the features and benefits of our indexable steel milling grade GC1230.

Hold Tight

Learn how to ensure inserts that seats are free from dirt or metal chips after machining.

Steel Machinability

The machinability of steel varies depending on the alloy elements, heat treatment, and manufacturing process.

Join us. Stay updated.

Sign up for our newsletter today