Troubleshooting for thread turning

Careful observation of the insert/cutting edge after machining can help to optimize results regarding tool life, thread quality, and cutting speed. Use this list of causes and solutions to different forms of insert wear as a reference for successful threading.

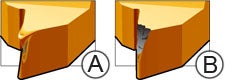

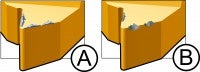

Plastic deformation  Starts as plastic deformation (A), |

|

|

Built-up edge (BUE)  BUE (A) and edge chipping (B) often |

|

|

Insert breakage  |

|

|

Rapid flank wear  |

|

|

Abnormal flank wear  Poor surface on one thread flank |

|

|

Vibration  |

|

|

Troubleshooting

Boring troubleshooting tips for both rough boring and fine boring, concerning chip... chevron_right

Troubleshooting

Main problems Spindle or tool runout is too high Wrong cutting data Built-up edge When... chevron_right

Troubleshooting

Use this list of causes and solutions for successful thread whirling. It is recommended... chevron_right

Troubleshooting

Oversized thread Cause Solution Wrong tolerance Wrong tap for application Incorrect... chevron_right