General Turning Formulas and Definitions

Find the cutting tool for your specific task and

get instant cutting data recommendations.

When machining in lathes, turning centers, or multi-task machines, calculating the correct values for different machining parameters like cutting speed and spindle speed is a crucial factor for good results. In this section, you will find the formulas and definitions needed for general turning.

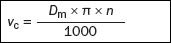

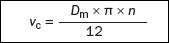

Cutting speed vc (m/min)  | Cutting speed vc (ft/min)  | |

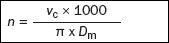

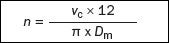

Spindle speed n (rpm)  | Spindle speed n (rpm)  | |

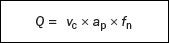

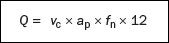

Metal removal rate Q (cm3/min)  | Metal removal rate Q (inch3/min)  | |

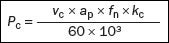

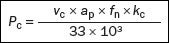

Net power Pc (kW)  | Net power Pc (HP)  | |

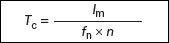

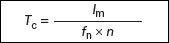

Machining time Tc (min)  | Machining time Tc (min)  |

| Symbol | Designation/definition | Unit, metric (imperial) |

|---|---|---|

| Dm | Machined diameter mm (inch) | mm (inch) |

| fn | Feed per revolution | mm/r (inch/r) |

| ap | Cutting depth | mm (inch) |

| vc | Cutting speed | m/min (feet/min) |

| n | Spindle speed | rpm |

| Pc | Net power | kW (HP) |

| Q | Metal removal rate | cm3/min (inch3/min) |

| hm | Average chip thickness | mm (inch) |

| hex | Maximum chip thickness | mm (inch) |

| Tc | Period of engagement | min |

| lm | Machined length | mm (inch) |

| kc | Specific cutting force | N/mm2 (N/inch2) |

| KAPR | Entering angle | degree |

| PSIR | Lead angle | degree |

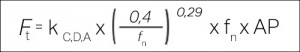

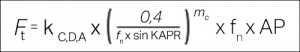

Tangential force, Ft

Kc 0.4: Specific cutting force at feed 0.4 mm/r

mc: Constant, depending on material. Use 0.29 as general value.

Tangential force, simplified formula

When the entering angle (KAPR) is 75 degrees or longer, sin KAPR is ~1. Then this simplified formula can be used.

Rule of thumb: Ft should not exceed 90% of maximum load stated for the bar used.