Boring formulas and definitions

In this section you find boring formulas and definitions needed for your boring operations, such as how to calculate correct boring cutting speed, feed per revolution and metal removal rate. When boring holes, correct values for different machining parameters are a crucial factor for good result.

| Metric | Inch |

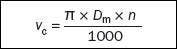

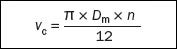

Cutting speed, (vc) m/min  | Cutting speed, (vc) ft/min  |

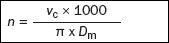

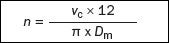

Spindle speed, (n) r/min  | Spindle speed, (n) rpm  |

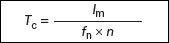

Machining time, (Tc) min  | Machining time, (Tc) min  |

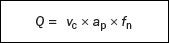

Metal removal rate, (Q) cm3/min  | Metal removal rate, (Q) inch3/min  |

Penetration rate, (vf) mm/min  | Penetration rate, (vf) inch/min  |

Feed per revolution, (fn) mm/rev  | Feed per revolution, (fn) inch/rev  |

Net power, Pc kW  | |

Torque, Pc Nm  |

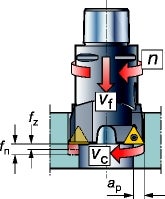

Cutting speed, vc

The boring tool rotates with a certain number of revolutions (n) per minute, generating a certain diameter (DC). This gives a specific cutting speed vc measured in m/min at the cutting edge. Cutting speed has a direct influence on tool life.

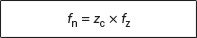

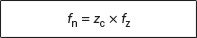

Feed, fn

The axial tool movement is called feed rate and is measured in mm/revolutions. The feed rate is obtained by multiplying the feed per tooth (fz) by the effective number of teeth (number of teeth generating final surface). The feed rate is the key value in determining the quality of the surface being machined and for ensuring that the chip formation is within the scope of the insert geometry.

Penetration rate, vf

The penetration rate means the speed of the axial movement and is strongly related to the productivity.

Metal removal rate, Q

Metal removal rate means how much material that can be removed in a certain time frame and is strongly related to the productivity for roughing.

Cutting depth, ap

The cutting depth is the difference between the uncut and the cut hole radius.

Entering angle, kr (º)

The cutting edge approach to the workpiece is expressed through the entering angle as the angle between the main cutting edge and the direction of feed.

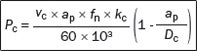

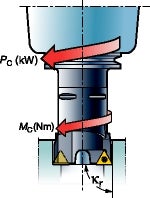

Net power, Pc

The power the machine must be able to provide to the cutting edges in order to drive the cutting action. The mechanical and electrical efficiency of the machine must be taken into consideration when selecting cutting data.

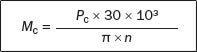

Torque, Mc

The torque value produced by the boring tool during cutting action, which the machine must be able to provide.