Vertical multi-task machines

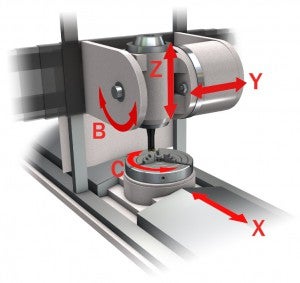

The primary benefit of a multi-task machine is that you can combine several cutting processes and set-ups in one single machine, reducing component set-ups and lead times. In a vertical multi-task machine the component is rotating around the vertical axis.

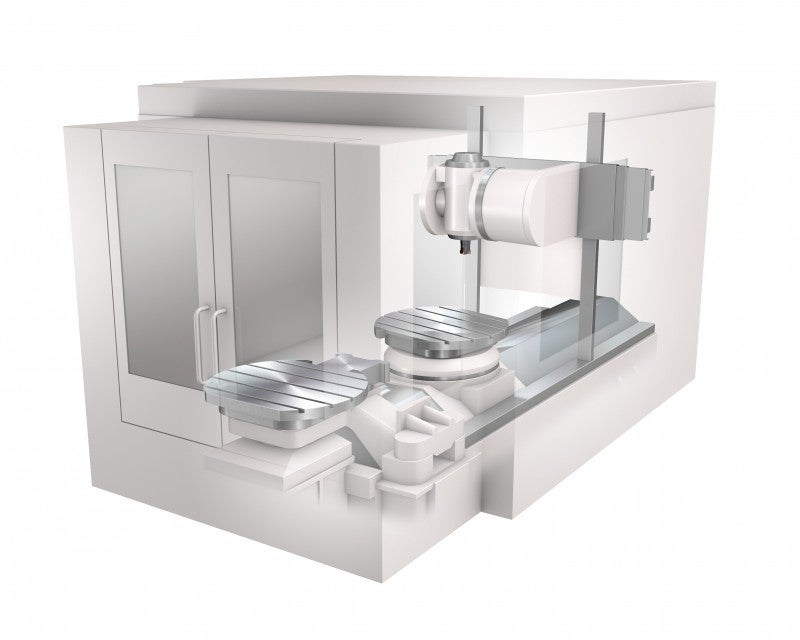

Vertical multi-task machine configuration

The vertical mill/turn machine has the component rotating around the vertical axis. The components are normally larger in diameter than for a horizontal multi-task machine and not requiring support via a steady rest, tailstock or sub-spindle.

This machine grouping has evolved from 5-axis machining centres with the addition of turning capability through increasing the rpm capability of the C axis (turning table) and adopting the spindle for stationary operations. Combining all operations on one machine thereby reducing component set-ups adds to its 5-axis machining capabilities.

To succeed with combining multiple and complex applications there are some key options that should be considered.

Spindle

The mix of static and rotating tools requires the broadest spindle capability combining a traditional machining centre and a lathe. High bending stiffness, torque transmission and accurate tool centre position are why Coromant Capto® is the most suitable interface for this machine concept.

Longer tool lengths will be needed for any internal operations making C8 (80 mm (3.150 inch) flange diameter) or C10 (100 mm (3.937 inch) flange diameter) the best choice for larger machines.

As well as providing the best stability, Coromant Capto® allows for the shortest gauge line and lowest tooling cost by removing the need for machine interface adaptors.

Read more about how to choose spindle

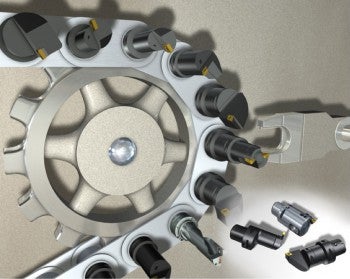

Magazine

A multi-task machine can replace a lathe and a machining centre and produce various components. It is important to allow ample space for tools in the magazine, for all operations and components, to support a quick change over from one job to another without the need to change tools.

Pallet

By using a pallet the component can be set-up in the fixture while the machine is still producing. This provides excellent machine utilization compared to setting up directly in the machine.

Right angle head adaptor

To be able to carry out internal milling operations the spindle nose adaption for supports and location will be needed to allow the main spindle to drive the auxiliary head. This head can be tool changed and stored in the magazine.

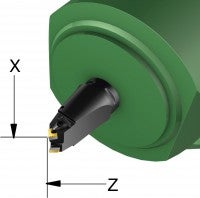

Interpolation turning

This machine option allows production of a symmetrical feature on a non-symmetrical component and reduces the need for engineered tools and feed out heads.

Multi-tool position

Multi-tool position, using turning holders with multiple cutting edges, has the double advantages of saving indexing time as well as magazine space. Spindle orientation, measuring and offsets of multiple positions are needed in the control.

High pressure pump

Most machines offer a high pressure coolant capability around 70 bar (1015 psi).Read more about coolant aspects

Multifunctional tools

The most important benefit for multi-task machines is the possibility to combine all operations on a component in one machine. However, drawbacks are increased tool indexing time compared to a turning centre, accessibility due to the B-axis head and compromised magazine space.

Multifunctional tools are developed for multi-task machines and addresses these issues to ensure the machine capabilities are maximized.