Milling inserts and grades for stainless steel

Find the right insert grade for your stainless steel milling operation among our PVD- and CVD-coated carbide grades and cermets for all machining conditions.

GC1040

A tough, PVD-coated grade with thin coating for roughing to finishing in unstable to stable conditions. GC1040 has a broad application area and can be easily applied in any milling application. The grade provides secure performance in difficult materials and tough conditions.Benefits and features

Find your grade

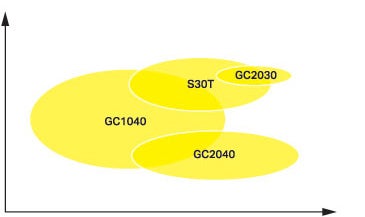

Our stainless steel insert grade assortment consists of CVD- and PVD-coated, cemented carbide grades and cermets for various machining conditions. Use the information below to find the right grade for your production.

Stable conditions Unstable conditions |  |

Low heat High heat (Small cutters (Large cutters |

GC1040

Tough, thin-coated PVD grade for finishing to roughing in unstable to stable, wet or dry conditions. Good choice for complex tool paths and sticky materials.

GC2040

Tough, medium-thick coated CVD grade designed for tough and demanding, medium to rough milling applications with poor stability in dry conditions. High feed rates, large diameters and radial engagements.

S30T

Medium-hard, thin-coated PVD grade to be used as a complement to GC1040 when stability is good and for high cutting speed demands in wet and dry conditions.

GC2030

Medium-hard, thin coated PVD grade for light roughing to finishing. Complement to GC1040 in good stability, for high cutting speeds in dry conditions.

Complementary grades

Highlights

Join us. Stay updated.

Sign up for our newsletter today