CoroPlus® Machining Insights

Manufacturing data analytics to improve your workshop efficiency and overall equipment effectiveness (OEE)

From data to actions

Get instant access to data about your machine- and tool availability, increased transparency and the opportunity to optimize your production processes.

See how it works

Use machine monitoring to configure real-time dashboard and reports, set watcher rules and create tickets for workshop improvements.

Get a quotation

Get started with collecting manufacturing data and machine tool monitoring. Get in contact with a sales representative and find out how.

Implement Industrial IoT and gain insights to your workshop through digital machine tool monitoring

Increasing OEE and productivity with machine monitoring.

Planning for availability in a smart factory requires transparency into all manufacturing operations. While manual collection of data and documentation becomes tedious and time-consuming, a connected CNC machine will offer new possibilities for transparency, optimized planning and a streamlined, error-free production. Real-time monitoring technology ensures decisions are based on facts for great production performance improvements. These are only a few examples what benefits machine monitoring creates in the manufacturing organization:

- Plant management: Increase operational efficiency and meet delivery demands with quality and profitability.

- Production engineering: Improve processes, facilitate capacity planning and secure that operations are carried out in a cost-efficient manner.

- Production management: Optimize operations and collaboration within workshops and between factories in order to reduce cost.

- Operators: Feedback and contribute to insights for optimization of the manufacturing process and machine operations.

Input through operator panel close to machine on the shop floor.

1. Collect real-time data

Uncover opportunities for manufacturing improvements and a deeper, more accurate, understanding of the manufacturing process with production data directly from your machines.

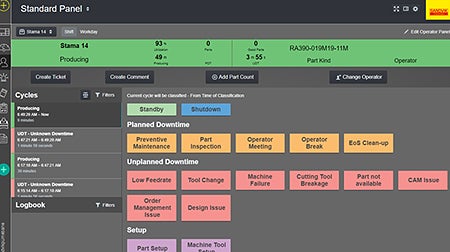

Monitor overall equipment effectiveness (OEE) in real time and add information directly from the operator on why a machine is not cutting metal to further improve understanding of stop causes and machine performance.

More downtime? Get machining insights through a browser on any device.

2. Get insights

Get insights on your machine health and performance with reports consisting of historical and real-time data. With access to data about machine downtime, stop causes, faults and alarm reasons it is possible to gain insights into optimization opportunities. Improvements in resource planning, asset management and cost and time prediction are enabled through insights facilitated through dashboards that accessible a browser on any device.

Tickets and tasks for follow up and optimization on monitor screen.

3. Take data-driven actions

Utilize tickets to improve communication throughout the workshop and take action on opportunities to optimize activities. This collaboration functionality enables actions with follow-up, problem solving, process improvement and act with speed in a collaborative environment.

Live demonstration

Monitoring of machine tool and cutting tool explained.

Features

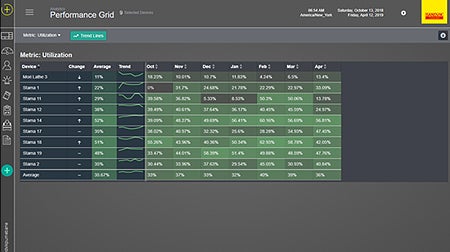

Machine utilization dashboards

Shop floor operations are visualized in real-time, where production events and disruptions are highlighted. Equipment utilization, part production, workforce productivity and asset health are monitored and easily managed with the machine monitoring system.

Performance reports

Historic shop floor performance is visualized; production insights, set-up time and unplanned as well as planned downtime duration.

Connect to other systems through APIs

Information exchange is enabled with enterprise applications, including ERP, EAM and MES systems using application programming interfaces (APIs)

Operator panel for input

Configurable panels enable operators to classify downtime reasons and improve shop floor communication. Comments can be added and tickets can be created.

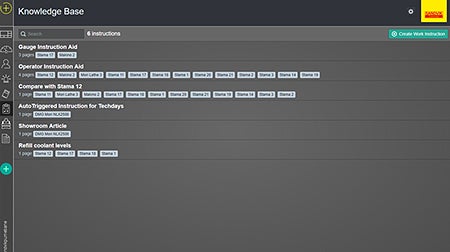

Operator instructions

Work instructions contained in a knowledge base are provided at any stage of the machining process. Instructions can be automatically triggered by an event in the machine tool.

Alerts for unattended machining

Notifications are sent to defined functions when an unattended machine needs attention. Alerts are triggered based on deviances from set process parameters.

Tool performance reports

Historic tool utilization is visualized; cutting duration per workpiece and machine tool.

Tickets

Tickets and improvement areas are documented and shared according to customizable rules. Notifications are sent by e-mail.

Included in the offer

When using CoroPlus® Machining Insights, your machines are connected and deliver data 24/7.

SilverCollect data from your machines for performance improvement. | GoldEngage operators to gain deeper insights and enable support for automation and unmanned machining. | PlatinumEnable performance improvements of your entire operations: machines, programs, tools and employees. | |

| Machine utilization dashboards | ✓ | ✓ | ✓ |

| Performance reports | ✓ | ✓ | ✓ |

| Connect to other systems through APIs | ✓ | ✓ | ✓ |

| Operator panel for input | ✓ | ✓ | |

| Operator instructions | ✓ | ✓ | |

| Alerts for unattended machining | ✓ | ✓ | |

| Tool performance reports | ✓ | ||

| Tickets | ✓ | ||

| Configurable dashboards and historical reports | ✓ |

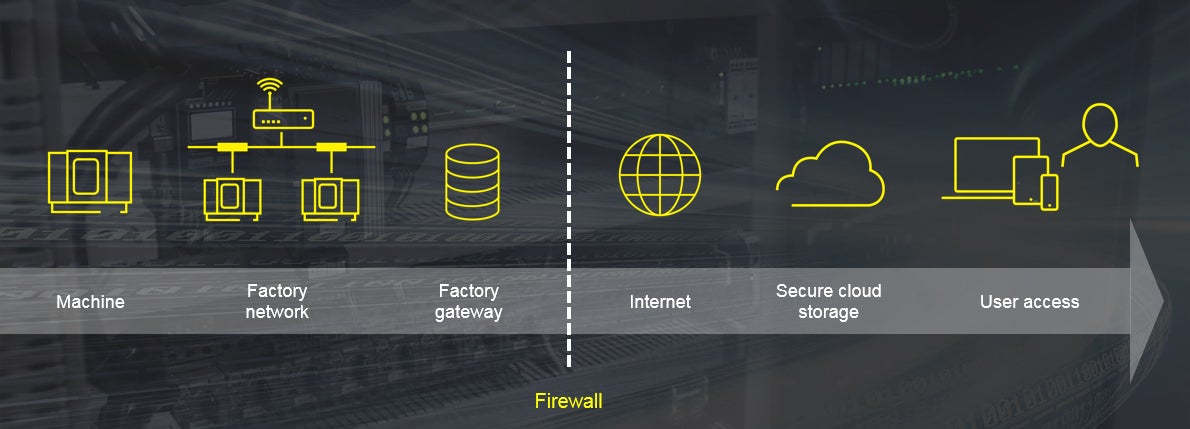

How machine monitoring works

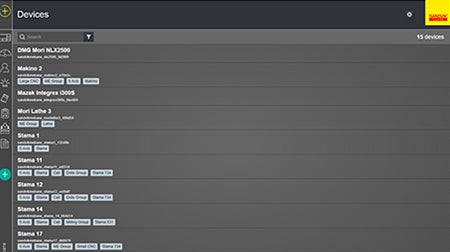

CoroPlus Machining Insights is a machine monitoring software which is deployed as a cloud-based application without any hardware installations. It is accessible from any tablet, phone or computer with an internet connection which enables remote monitoring.

Sensors can be attached and make most machines younger than 10 years old connected with the monitoring system. For details, consult your local Sandvik Coromant representative. The machines need to be connected to an Ethernet factory network with a server. Machine data is collected from the machines via the factory network.

A software program is installed on for example a factory server provided. The software program collects data from machine tools via the factory network which is then streamed as compressed data to the platform in the cloud.

Users access the machine monitoring system using any modern and up-to-date web browsers. Recommended browsers are Google Chrome and Mozilla Firefox.

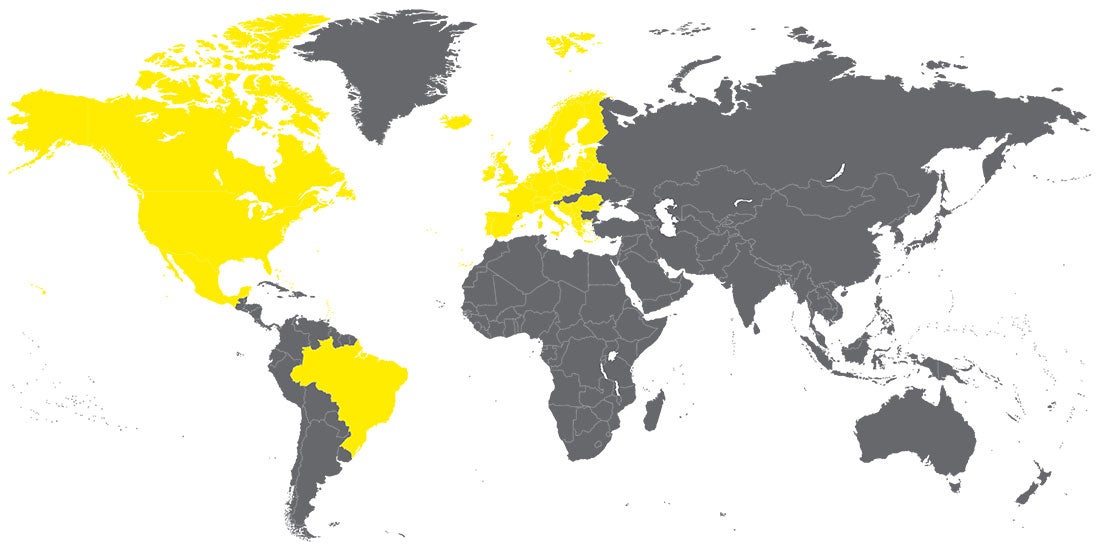

Availability

The first introduction of CoroPlus® Machining Insights is available in the countries marked with yellow color on the map below.

Resources

Join us. Stay updated.

Sign up for our newsletter today