Troubleshooting in parting and grooving

Bad surface  |

|

Bad surface on aluminum  |

|

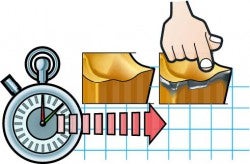

Poor chip breakage  |

|

Vibration  |

|

Poor tool life  |

|

Insert wear

Insert edge problems

To achieve optimized cutting data, the best possible workpiece quality, and tool life, always remember to check the insert edge. At low speeds, built-up edge (BUE) and chipping are the main insert edge problems; at high speeds, plastic deformation (PD), flank wear, and crater wear are the main problems. The solutions are presented in the following table.

Built-up edge (B.U.E)  |

|

| |

| When parting to center and on stainless material, it is almost impossible to avoid BUE. It is important to minimize this phenomenon by using the solutions above. | |||

Chipping/breakage  |

|

| |

Plastic deformation (PD)  |

|

| |

Flank wear  |

|

| |

Crater wear  |

|

| |

Notch wear  |

|

| |

Troubleshooting

Boring troubleshooting tips for both rough boring and fine boring, concerning chip... chevron_right

Troubleshooting

Main problems Spindle or tool runout is too high Wrong cutting data Built-up edge When... chevron_right

Troubleshooting

Use this list of causes and solutions for successful thread whirling. It is recommended... chevron_right

Troubleshooting

Oversized thread Cause Solution Wrong tolerance Wrong tap for application Incorrect... chevron_right