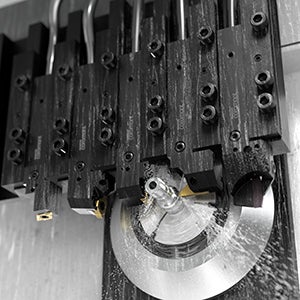

QS™ Micro holding system

Streamlining small part machining

Small part machining made easy

Quick-change solution QS™ Micro delivers unprecedented precision in sliding head machines. It achieves this without compromising process security, thanks to its rigid holding mechanism that minimizes vibrations.

Tailored set-ups through modular magic

With its extensive range of cutting heads and shank adaptors, QS™ Micro offers a multitude of configurations. Thanks to the simple set-up and quick tool changes, machine utilization is maximized, increasing productivity.

Improve efficiency with Y-axis machining

CoroTurn® 107 and CoroCut® XS provide cutting heads designed for Y-axis machining, offering benefits such as enhanced stability and improved chip evacuation.

Application

- Cutting heads for general turning, parting and grooving, and threading in families CoroTurn® 107, CoroCut® 2, CoroCut® XS and CoroThread® 266

- For small part machining and sliding head machines

- Covers the majority of the main industry segments, such as general engineering, automotive, aerospace, and medical

- Grades and geometries for all application areas

- Y-axis tools for CoroTurn® 107 and CoroCut® XS

ISO application area

Cutting heads

CoroTurn® 107

For turning

- Optimized for external turning of slender components

- Sharp cutting edges and excellent chip control ensure a soft cutting action and low cutting forces, providing an exceptional surface finish

CoroCut® 2

For parting off and grooving

- Brings a new level of process security and productivity to your machining

- With this versatile tool concept, you’ll get the stability you need, while keeping cost per component down and metal cutting efficiency up

CoroCut® XS

For turning, parting off, grooving and threading

- Tangentially mounted system for precision machining in sliding head machines and lathes

- The extremely sharp cutting edges perform best at low feeds

CoroThread® 266

For threading

- First choice for external thread turning

- Wide standard assortment of thread profiles with dedicated grades and geometries for all materials

Product range

CoroTurn® 107

Tools for insert sizes:

- CCMT 06/09

- DCMT 07/11

- VCMT/VBMT 11

Turning and profiling

- Diameter: 6–40 mm (0.236–1.57 inch)

- RE ≥0.02 mm (0.0008 inch)

CoroCut® 2

Tools for insert sizes:

- E (2 mm (0.079 inch))

- F (2.5 mm (0.098 inch))

- G (3 mm (0.118 inch))

Parting off

- Diameter: =<32 mm (=<1.25 inch)

- Cutting width: ≥2 mm (0.08 inch)

Grooving

- Max. cutting depth: =<16 mm (=<0.63 inch)

- Cutting width: 2–3 mm (0.08–0.118 inch)

CoroCut® XS

Tools for insert size: 3, right and left-hand

Turning

- Diameter: 1–8 mm (0.040–0.315 inch)

- RE ≥0.03 mm (0.001 inch)

Parting off

- Diameter: <16 mm (0.63 inch)

- Cutting width: ≥0.7 mm (0.03 inch)

Grooving

- Max. cutting depth: 1.3–3.7 mm (0.05–0.15 inch)

- Cutting width: 0.5–2.5 mm (0.02–0.098 inch)

Threading

- Thread forms: M, UN, NPT, WH, V-profile

- Diameter: 1–8 mm (0.040–0.315 inch)

CoroThread® 266

Tools for insert size: 16, right and left-hand

Threading

- Most thread forms

- Multi- or single-point profiles

- Diameter: 8–40 mm (0.315–1.57 inch)

Highlights

Animation: QS™ Micro

Watch the unparalleled precision and modularity of quick-change solution QS™ Micro

Knowledge section: sliding head machines

This section covers in-depth knowledge and configuration tips. Brush up on your small part machining knowledge here.

Join us. Stay updated.

Sign up for our newsletter today