Tools for sliding head machines

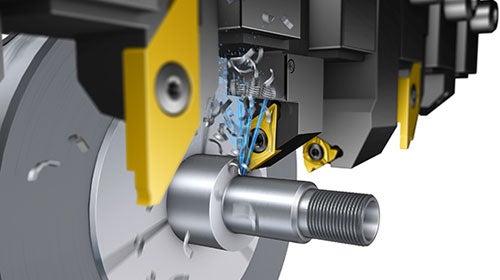

In the realm of precision engineering, mastering the production of thousands of intricate parts demands more than just skill—it requires the right tools for the job. Our extensive selection of tooling options is meticulously crafted to enhance the capabilities of sliding head machines, ensuring optimal performance and efficiency. From intricate components to complex projects, our comprehensive range empowers you to tackle every manufacturing challenge with precision and ease, maximizing your productivity and success in the competitive market of sliding head machining.

Tooling systems

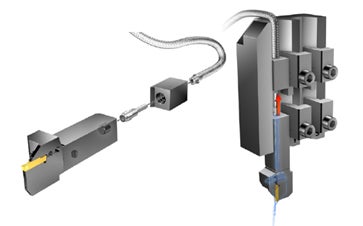

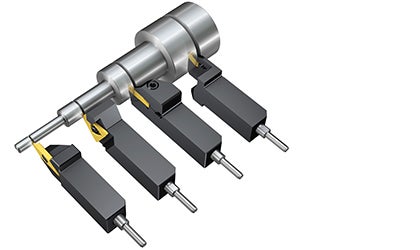

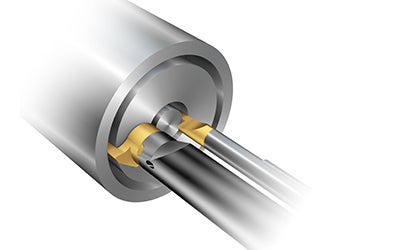

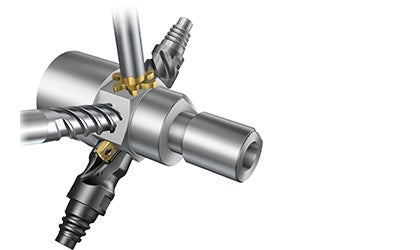

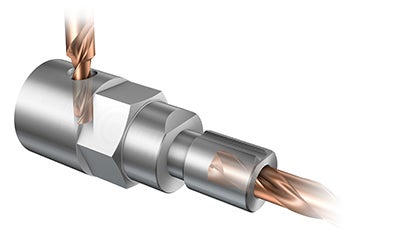

QS™ Micro holding system

- Quick-change, modular tooling system for sliding head machines

- Easy-to-connect through coolant functionality

- Cutting heads for general turning, parting and grooving, and threading

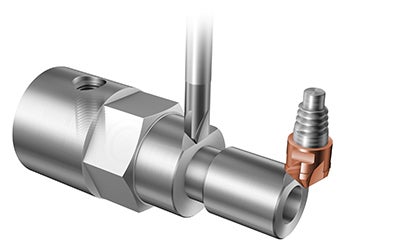

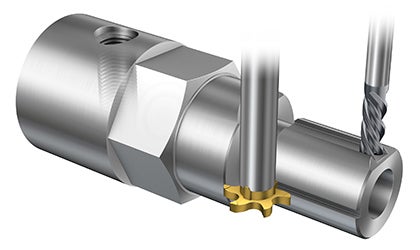

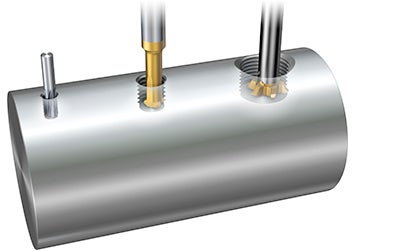

QS™ holding system

- Quick change swiss shank system for sliding head machines

- Available with precision coolant, which improves chip control, tool life and component quality

External turning

CoroTurn® 107

- Turning and profiling

- Diameter: 6–40 mm (0.236–1.57 inch)

- RE ≥0.02 mm (0.0008 inch)

CoroCut® XS

- Turning, profiling and back turning

- Diameter: 1–8 mm (0.040–0.315 inch)

- RE ≥0.03 mm (0.001 inch)

Parting off

CoroCut® 2

- Diameter: 12–32 mm (0.5–1.25 inch)

- Cutting width: ≥1.5mm (0.06 inch)

CoroCut® XS

- Diameter: <8 mm (0.315 inch)

- Cutting width: ≥0.7 mm (0.03 inch)

CoroCut® 3

- Diameter: 6–12 mm (0.24–0.5 inch)

- Cutting width: ≥1 mm (0.04 inch)

CoroCut® 1-2

- Diameter: 12–32 mm (0.5–1.25 inch)

- Cutting width: ≥1.5 mm (0.06 inch)

CoroCut® QD

- Diameter: ≥20 mm (0.79 inch)

- Cutting width: ≥1 mm (0.04 inch)

External grooving

CoroCut® 2

- Diameter: 12–32 mm (0.5–1.25 inch)

- Cutting width: ≥1.5mm (0.06 inch)

CoroCut® XS

- Max. cutting depth: 1.3–3.7 mm (0.05–0.15 inch)

- Cutting width: 0.5–2.5 mm (0.02–0.098 inch)

CoroCut® 3

- Max. cutting depth: 3–6 mm (0.12–0.24 inch)

- Cutting width: 0.5–3.18 mm (0.02–0.12 inch)

CoroCut® 1-2

- Max. cutting depth: 6–16 mm (0.24–0.63 inch)

- Cutting width: 1.5–3 mm (0.06–0.13 inch)

CoroCut® QD

- Max. cutting depth: >16 mm (0.63 inch)

- Cutting width: 1–3 mm (0.04–0.12 inch)

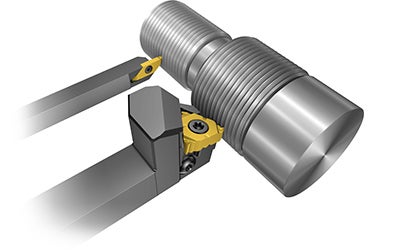

External threading

CoroThread® 266

- Most thread forms

- Multi- or single-point profiles

- Diameter: 8–40 mm (0.315–1.57 inch)

CoroCut® XS

- Thread forms: M, UN, NPT, WH, V-profile

- Diameter: 1–8 mm (0.040–0.315 inch)

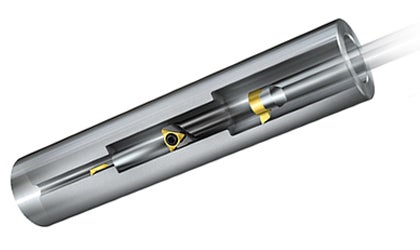

Internal turning

CoroTurn® XS

- Turning, profiling, back boring

- Min. hole diameter: 0.3 mm (0.012 inch)

CoroTurn® 107

- Turning, profiling

- Min hole diameter: 6 mm (0.236 inch)

CoroCut® MB

- Turning, profiling, back boring

- Min. hole diameter: 10 mm (0.394 inch)

Internal grooving

CoroTurn® XS

- Max. cutting depth: 2.5 mm (0.100 inch)

- Cutting width 0.78 mm (0.031 inch)

- Min. hole diameter: 4.2 mm (0.165 inch)

CoroCut® MB

- Max. cutting depth: 8 mm (0.315 inch)

- Cutting width: 0.73 mm (0.029 inch)

- Min. hole diameter: 10 mm (0.394 inch)

Internal threading

CoroThread® 266

- Pitch: 0.5–8 mm (32–3 threads/in)

- Min. hole diameter: 12 mm (0.472 inch)

- Thread forms: M, UN, WH, PT, NT, NF, RN, MJ, UNJ, TR, AC, SA

CoroTurn® XS

- Pitches: 0.5–3 mm (32–16 threads/in)

- Min. hole diameter: 4mm (0.157 inch)

- Thread forms: M, UN, WH, NPT, TR and V-forms

CoroCut® MB

- Pitches: 0.5–3 mm (32–8 threads/in)

- Min. hole diameter: 10 mm (0.394 inch)

- Thread forms: M, UN, NPT, TR, AC, SA

T-max® U-lock

Face grooving

CoroTurn® XS

- Min. hole diameter: 6mm (0.24 inch)

- Max. cutting depth: 2–30 mm (0.08–1.18 inch)

- Cutting width: 1–5 mm (0.04–0.2 inch)

CoroCut® MB

- Min. groove diameter: 12 mm (0.47 inch)

- Max. cutting depth: 1.5–10 mm (0.06–0.394 inch)

- Cutting width: 1–4 mm (0.04–1.57 inch)

Chamfer milling

CoroMill® Plura

- Chamfer angles: 45° and 60°

- Convex workpiece chamfer radii: 0.5–6.0 mm (0.020–0.236 inch)

CoroMill® 316

- Chamfer angles: 15°, 30°, 45°, 49° and 60°

- Convex workpiece chamfer radii: 1.5–8.0 mm (0.059–0.315 inch)

CoroMill® 326

- Chamfer angle: 45°

- Min. hole diameter: 5.8 mm (0.228 inch)

Face milling

CoroMill® Plura

- High feed face milling cutters

- Milling cutter diameter: 4–20 mm (0.157–0.787 inch)

CoroMill® 316

- High feed face milling cutters

- Milling cutter diameter: 10–25 mm (0.375–1.00 inch)

CoroMill® 327

- Milling cutter diameter: 20–32 mm (0.75–1.25 inch)

CoroMill® 490

- Milling cutter diameter: 20–32 mm (0.75–1.25 inch)

Slot milling

Drilling

Thread milling

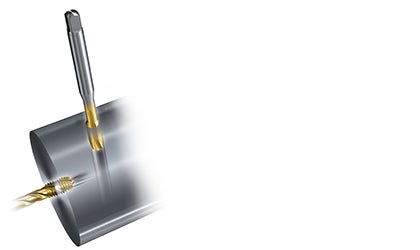

Tapping

CoroTap® -K

Thread whirling

CoroMill® 325

- Screw diameter: 3–10 mm (0.118–0.394 inch)

- Thread forms: HA and HB

Highlights

Catalogue: Tools for sliding head machines

This catalogue guides you through our comprehensive range of precision tools for machining small parts in sliding head machines.

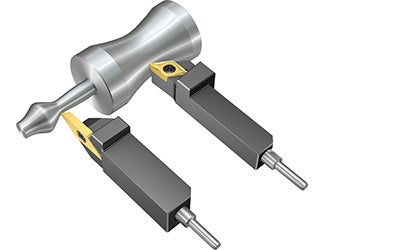

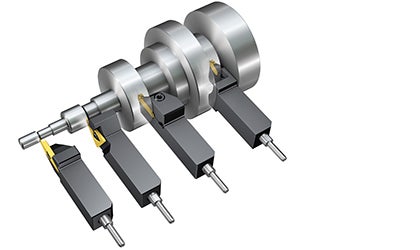

Maximized machine utilization

QS™ holding system is a quick change system developed specifically for sliding head machines. The system of tool holders, stops and wedges offer stable tool clamping and secure insert edge position for good repeatability and accuracy.

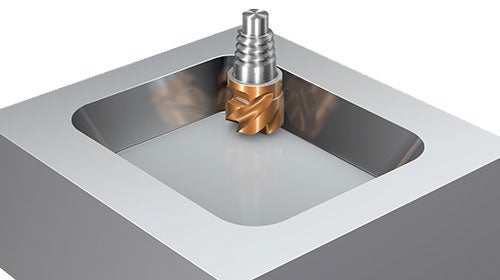

Medical solutions

Machining medical implants requires tools that meet very high technical demands. We offer a large range of advanced tooling and machining solutions for medical devices. They are able to meet exact specifications, even with difficult materials.

How to get the best machining result

Tool and cutting data recommendations

Struggling to find the right tool for the job? CoroPlus® Tool Guide offers quick and accurate tool recommendations on all your digital devices.

Find the right QS™ wedge

Do you need help finding a suitable QS™ wedge for your sliding head machine? Find the correct tooling combination of wedge and holder depending on machine tool brand and model.

Knowledge through e-learning

Want to know how to improve productivity and use the tools? Learn the fundamentals in metal cutting by using our e-learning programme.

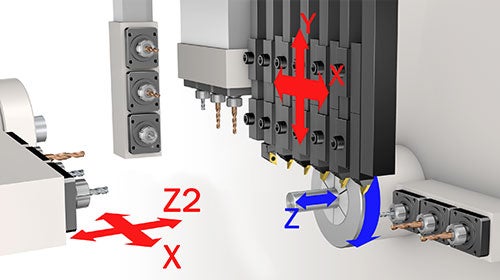

Machine configurations

Get tips on how to configure your sliding head machine and other good to know information when it comes to this machine type.

Micro drills

Solid carbide and polycrystalline diamond (PCD) micro drills ideal for precision machining in small parts

How to use Coromant EH

Get tips on torque, usage area and other valuable information related to modular system Coromant EH.

Tools for Sliding Head Machines

In the machining industry, precision is critical, especially when working with sliding head machines or CNC sliding head lathes. Our comprehensive range of tools for sliding head machines is designed to deliver optimal performance for producing precision components in industries such as automotive and medical. Whether you're turning, parting, grooving, or profiling, our tool holders and tool post solutions enhance productivity and ensure efficient machining.

QS™ Holding System and QS™ Micro Holding System

Both the QS™ holding system and the QS™ Micro holding system are optimized for sliding head lathes, providing quick-change capability, through-coolant functionality, and stable clamping for better tool life and chip control. These systems help you achieve precision in turning, grooving, and threading operations. The QS™ Micro holding system is particularly suited for micro-scale precision components, ensuring maximum accuracy.

Our tool holders are designed to minimize downtime and improve your sliding head machine's performance, making them an ideal investment for companies aiming to increase production and improve productivity.

Join us. Stay updated.

Sign up for our newsletter today