CoroCut® 1-2

Versatile parting and grooving

Versatile parting and grooving

With more than 700 standard inserts, CoroCut 1-2 covers all parting and grooving applications in most materials, from standardized grooves to parting off and profiling in heat resistant super alloys.

Cost efficiency with two edges

The two-edge inserts are firmly positioned in the railed insert seat giving cost-efficiency and stable performance.

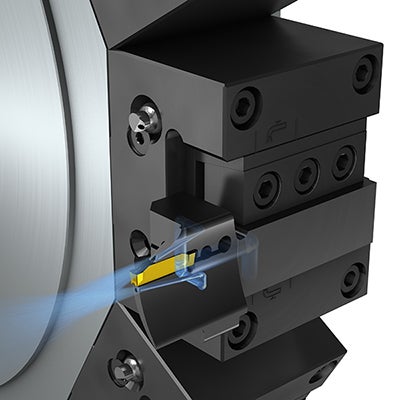

Secure and efficient machining

In grooving, chips easily get stuck in the curved groove, leading to insert breakage. CoroCut 1-2 tools with precision coolant securely evacuate the chips for an undisrupted machining process.

Application

- Parting, external grooving, face grooving, internal grooving, profiling and hard part turning

- Roughing to finishing

In parting off and external grooving CoroCut® 1-2 is a cost-efficient solution to depths where the 2-edged inserts can be used.

Product variants

Tool holding

- Coromant Capto®, VDI, and HSK-T for connecting QS shanks and parting blades in turning centres

- QS™ stops for connecting QS shanks and swiss tools, machine specific adaptors

- Rectangular shanks and boring bars

Plug and play adaptors for easy coolant connection

CoroTurn SL blades

CoroTurn SL cutting blades enable a wide range of tool combinations from a small inventory of adaptors and cutting heads.

Insert geometries

- Parting off: -CF; -CM; -CR; -CS

- Grooving and side turning: -TF; -TM

- Grooving: -GF;-GM; -GR

- Profiling: -RO; -RM; -RE

- WIPER: -CF; -TF

- Hart part turning: -XB

Insert grades

- PVD: GC1105; GC1125; GC1145

- CVD: GC1135; GC4325; S205; CG3115

- CBN: CB7015, CB7025, CB7105 and CB7115

- PCD: CD10

- Ceramic: CC6220

- Uncoated: H13A; H10F

Highlights

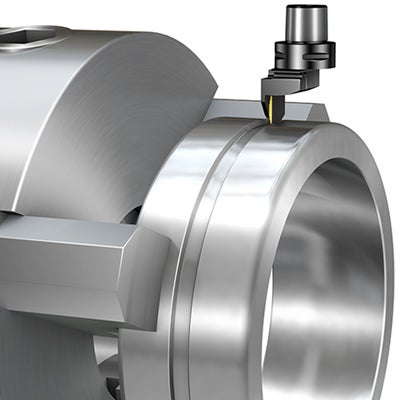

Access with angled inserts

Angled inserts are perfectly formed for those difficult-to-access grooves in e.g. the turbine disc eliminating the need for special tools.

Hard part turning with CoroCut 1-2

The new –XB geometry for hard part turning can operate at very high feed rates, up to 1.2 mm/rev (0.047 in/rev) without compromising surface finish.

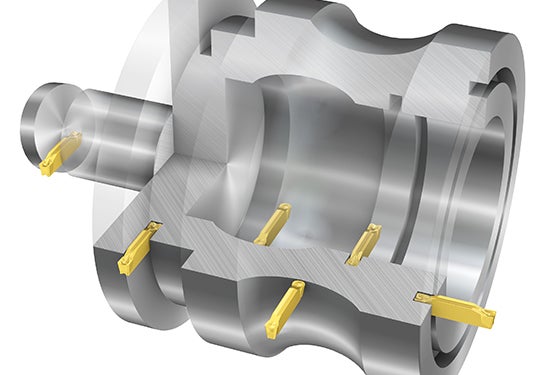

Seal fin grooving

Generating small radii profiles with correct profile width puts high demands on a robust tooling solution. CoroCut 1-2 for seal fin grooving is available in insert width 1.5 and 2 mm (0.059 and 0.079 inch).

Join us. Stay updated.

Sign up for our newsletter today