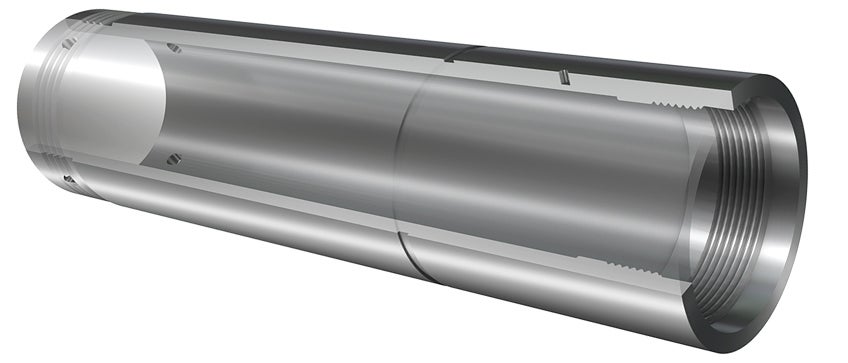

Solutions for cost effective and high-quality machining of oil and gas mandrel features

A mandrel is a bar, shaft or spindle around which other components are arranged or assembled.

The term has been extended in oil and gas well terminology to include specialized tubular components that are key parts of an assembly or system, such as gas-lift mandrel or packer mandrel.

Facts and component characteristics

Materials

- Super 13Cr – a low carbon martensitic steel with high corrosion resistance

Properties

- Outer diameter ≈ 100 mm (4 inch)

- Inner diameter ≈ 75 mm (3 inch)

- Length ≈ 480 mm (19 inch)

- Max 28 HRc

Key component features/operations

- External turning

- Internal turning

- Internal thread

- External groove

Tooling solutions for machining of oil and gas – Mandrel body features

PrimeTurning™ - all directional turning with extraordinary productivity for internal and external turning applications

With the CoroTurn® Prime SL head solution it is now possible to use our PrimeTurning™ methodology for internal turning. The inside-out machining capability allows for excellent chip evacuation and chip control.

Silent Tools™ - Overcome vibrations when machining long overhangs

To keep chips flying at a high rate, it is important to reduce vibration as much as possible. Silent Tools™ dampened boring bars minimize vibrations. In this way, a high metal removal rate is possible.

CoroTurn® SL adaptor interface

CoroTurn® SL is a modular system of adaptors and cutting heads with which you can build customized tools for a variety of turning applications with a minimum amount of items. The robust coupling and many combination possibilities makes it ultimate for building a tool for machining complex components.

Coromant Capto® is a modular quick-change tooling concept offering three systems in one. Benefits with Coromant Capto® are:

- Flexible with extensive modularity

- High basic stability and accuracy

- Minimized tool inventory

- Reduced set-up time

CoroCut® 1-2 - Versatile parting and grooving

With more than 700 standard inserts, CoroCut 1-2 covers all parting and grooving applications in most materials, from standardized grooves to parting off and profiling in heat resistant super alloys.

Customer values using Sandvik Coromant tools and solutions

- High productivity thanks to the long and predictable tool life of GC4325

- Secure process with good chip control thanks to cutting head with CoroTurn® HP nozzle technology

- Vibration- and trouble-free machining with long overhang

- High productivity – major time savings with Silent Tools™