CoroMill® MH20

高进给型腔铣削

说明

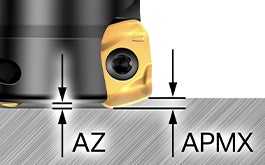

最大切深 (APMX)

最大切深为:

IC06: 0.8毫米 (0.031英寸)

IC08: 1.2毫米 (0.047英寸)

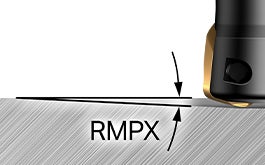

坡走角度 (RMPX)

坡走铣角度为:

IC06:3.6°–10.1°

IC08:1.7°–10.7°

编程半径 (REEQ)

编程圆角:

IC06:2.0毫米 (0.079英寸)

IC08:2.5毫米 (0.098英寸)

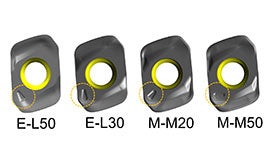

槽型标记

刀片采用显眼的标记来区分槽型。

应用技巧

成功坡走铣的三大关键

坡走铣是型腔加工时切入工件的一种有效方法。有3个关键因素,必须正确应用才能成功完成坡走铣工序。 下方“建议” (recommendations) 部分提供切削参数建议,或者可在我们网站的“知识” (Knowledge) 版块更详细了解坡走铣。

插铣

进行插铣加工时,您应使用超密齿,以确保有两个齿在切削。了解更多重要的插铣技巧,保证插铣工序的成功。 下方“建议” (recommendations) 部分提供切削参数建议,或者可在我们网站的“知识” (Knowledge) 版块更详细了解插铣。

建议

编码规则

刀体

| M | H | 2 | 0 | - | (A) | R | 0 | 2 | 5 | A | 2 | 5 | - | 0 | 6 | M |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

- 铣削

- 高进给

- 系列 = 2

- 版本 = 0

- 英制刀具

- R = 右手

- DCX

- 接口类型

A/O = 圆柱柄 (公制/英制)

Q/R = 心轴 (公制/英制)

EH = EH接杆

- 接口尺寸

- 刀片尺寸

- 齿距: L/M/H

刀片

| M | H | 2 | 0 | - | 0 | 8 | 0 | 4 | 2 | 5 | M | - | M | 2 | 0 | 1 | 1 | 3 | 0 | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||||||||||

- 铣削

- 高进给

- 系列 = 2

- 版本 = 0

- 刀片尺寸

- 厚度

- 编程半径

- 公差等级

E: 周边磨制

M: 直接压制

- 槽型

- 材质

槽型

|  |  |  |

| E-L30 | E-L50 | M-M20 | M-M50 |

| 周边磨制槽型 | 周边磨制槽型 | 直接压制槽型 | 直接压制槽型 |

| ISO S和M | ISO S和M | ISO P和H | ISO P |

|

|

|

|

切削参数,进给推荐值

| ISO范围 | 材质 | 刀片尺寸 | 槽型 | fz,起始值 (最小-最大) | |

| mm/z | 英寸/转 | ||||

| ISO S (TiAl6V4) | S30T, S40T, GC2040 | IC06 | E-L30 | 0.3 (0.1–0.6) | .012 (.004–.024) |

| IC08 | E-L30 | 0.45 (0.1–0.6) | .018 (.004–.024) | ||

| IC06 | E-L50 | 0.35 (0.1–0.6) | .014 (.006-.024) | ||

| IC08 | E-L50 | 0.5 (0.1–0.6) | .020 (.006-.024) | ||

| ISO S (Inconel) | S30T, S40T, GC2040 | IC06 | E-L50 | 0.35 (0.1–0.6) | .014 (.006-.024) |

| IC08 | E-L50 | 0.5 (0.1–0.6) | .020 (.006-.024) | ||

| ISO M (316L) | GC1040, GC2040, S30T, S40T | IC06 | E-L30 | 0.3 (0.2–0.8) | .012 (.008–.031) |

| IC08 | E-L30 | 0.45 (0.2–0.8) | .018 (.008–.031) | ||

| IC06 | E-L50 | 0.35 (0.2–0.8) | .014 (.008-.032) | ||

| IC08 | E-L50 | 0.5 (0.2–0.8) | .020 (.008-.032) | ||

| ISO P | GC1130, GC4340 | IC06 | M-M20 | 0.6 (0.2–0.8) | .024 (.008–.031) |

| IC08 | M-M20 | 0.7 (0.2–1.0) | .028 (.008–.039) | ||

| IC06 | M-M50 | 0.8 (0.45–1.0) | .031 (.018–.039) | ||

| IC08 | M-M50 | 1.0 (0.45–1.3) | .039 (.018–.051) | ||

| ISO H | GC1010, GC1130 | IC06 | M-M20 | 0.45 (0.15–0.6) | .018 (.006–.024) |

| IC08 | M-M20 | 0.55 (0.1–0.8) | .022 (.039–.031) | ||

切削参数,切削速度推荐值

| ISO范围 | 材质 | vc, (最小值-最大值) | |

| m/min | 英尺/分钟 | ||

| ISO S (TiAl6V4) | S30T | 75–115 | 246–377 |

| S40T | 75–100 | 246–328 | |

| GC2040 | 31–40 | 102–131 | |

| ISO S (Inconel) | S30T | 40–60 | 131–197 |

| S40T | 40–60 | 131–197 | |

| GC2040 | 40–60 | 131–197 | |

| ISO M (316L) | GC1040 | 115–180 | 377–591 |

| GC2040 | 160–225 | 525–738 | |

| S30T | 155–250 | 509–820 | |

| S40T | 165–235 | 541–771 | |

| ISO P | GC1130 | 150–265 | 492–869 |

| GC4340 | 150–265 | 492–869 | |

| ISO H | GC1010 | 75–115 | 246–377 |

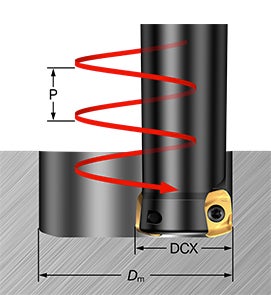

螺旋坡走铣

| 公制刀具 (DCX) | 英寸刀具 (DCX) | IC06刀片 | IC08刀片 | ||||||

| 最大ap 0.8mm (.031英寸) | 最大ap 1.3 mm (.051英寸) | ||||||||

| 最大坡走角度 (RMPX) | 最大Dm | 平底孔最小Dm | 最小Dm | 最大坡走角度 (RMPX) | 最大Dm | 平底孔最小Dm | 最小Dm | ||

| 5/8 | 10.1° | 31.8 | 23.4 | 22.4 | |||||

| 16 | 9.5° | 32.0 | 23.6 | 22.6 | |||||

| 3/4 | 6.5° | 38.2 | 29.8 | 28.8 | 10.7° | 38.2 | 27.6 | 26.1 | |

| 20 | 5.8° | 40.0 | 31.6 | 30.6 | 9.6° | 40.0 | 29.4 | 27.9 | |

| 25 | 3.7° | 50.0 | 41.6 | 40.6 | 5.7° | 50.0 | 39.4 | 37.9 | |

| 1 | 3.6° | 50.8 | 42.4 | 41.4 | 5.5° | 50.8 | 40.2 | 38.7 | |

| 11⁄4 | 3.6° | 63.6 | 53.0 | 51.5 | |||||

| 32 | 3.6° | 64.0 | 53.4 | 51.9 | |||||

| 11⁄2 | 2.7° | 76.2 | 65.6 | 64.1 | |||||

| 40 | 2.5° | 80.0 | 69.4 | 67.9 | |||||

| 44 | 2.3° | 88.0 | 77.4 | 75.9 | |||||

| 50 | 1.7° | 100.0 | 89.4 | 87.9 | |||||

| 2 | 1.7° | 101.6 | 91.0 | 89.5 | |||||

| 52 | 1.6° | 104 | 93.4 | 91.9 | |||||

| 54 | 1.5° | 108 | 97.4 | 95.9 | |||||

| 63 | 1.1° | 126 | 115.4 | 113.9 | |||||

| 21⁄2 | 1.1° | 127 | 116.4 | 114.9 | |||||

| 66 | 1.0° | 132 | 121.4 | 119.9 | |||||

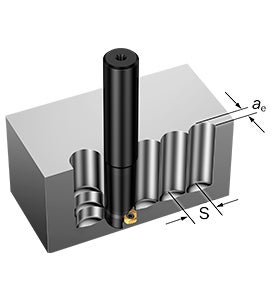

插铣

悬伸L ≤ 3×D

注意!S必须≤ 20 mm

| IC | 最大ae,mm (英寸) | 进给,mm/z (英寸/齿) |

| 06 | 4 (0.157) | 0.10 (0.05–0.15) (0.004 (0.002–0.006)) |

| 08 | 5.5 (0.217) | 0.12 (0.05–0.15) (0.005 (0.002–0.006)) |

悬伸L ≥ 3×D

注意!S必须≤ 20 mm

| IC | 最大ae,mm (英寸) | 进给,mm/z (英寸/齿) |

| 06 | 4 (0.157) | 0.08 (0.05–0.15) (0.003 (0.002–0.006)) |

| 08 | 5.5 (0.217) | 0.1 (0.05–0.15) (0.004 (0.002–0.006)) |

加入我们,获取最新信息!

现在订阅我们的新闻快讯