CoroDrill® DS20

4–7×DC刀具钻削具有出色的可靠性、可预测性和穿透率。

成功案例

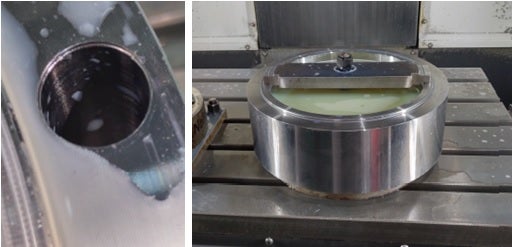

| 零件: | 轴承 |

| 材料: | 硬化P2.5.Z.HT (42CrMo4),HB 330 |

| 工序: | 通孔,Ø30 mm ,深度:123 mm |

| 机床: | 立式机床中心,ISO 50锥柄 |

| 冷却液: | 乳化液,20巴 |

刀具寿命

+55%

生产周期缩短

50%

| 其他品牌 | CoroDrill® DS20 | |

| 刀具 | - | DS20-D3000L32-05 |

| 刀片 | - | DS20-0407-C-M7 1344 DS20-0407-P-M7W 4334 |

| vc,m/min | 150 | 130 |

| n,rpm | 1592 | 1379 |

| vf,mm/min | 111 | 220 |

| fn,mm | 0.07 | 0.16 |

| 切削时间 (分钟) | 66.2 | 33.4 |

| 3金属去除率,cm/min | 78.75 | 156 |

| 刀具寿命,件/切削刃,m (英尺) | 6 (19.7) | 9.3 (30.5) |

| 结果: | 凭借CoroDrill® DS20,客户获得了更可靠的加工过程,且刀具寿命和性能都得到了提升。 |

成功案例

| 零件: | 热交换板 |

| 材料: | P1.1.Z.AN,HB 140 |

| 工序: | 管板堆钻加工,50%吃刀;在9.5 mm 和15.9 mm 的厚板材中钻削半孔 |

成本降低

61%

生产周期缩短

50%

| 其他品牌 | CoroDrill® DS20 | |

| 刀具 | - | DS20-2000L25-04 |

| 刀片 | - | DS20-0205-C-M7 1344 DS20-0205-P-M7W 4344 |

| vc,m/min | 113 | 213 |

| n,rpm | 1800 | 3397 |

| vf,mm/min | 90 | 170 |

| fn,mm | 0.05 | 0.05 |

| 切削时间 (分钟) | 9.99992 | 4.99996 |

| 刀具寿命,件 | 60 | 60 |

| 结果: | 客户希望提高生产率和降低成本,但是不影响孔的质量。这样的效果通过CoroDrill® DS20实现了。 |

成功案例

| 零件: | 驱动轴齿轮 |

| 材料: | (20CrNi2Mo),HB 150~170 |

| 工序: | 钻削通孔,Ø 27 +/-0.5 mm ,深度:70 mm |

| 机床: | 立式机床中心,BT50 |

| 冷却液: | 乳化液,内冷,20巴 |

+200%

刀具寿命

| 其他品牌 | CoroDrill® DS20 | |

| 刀具 | - | DS20-D2700L32-04 |

| 刀片 | - | DS20-0306-C-L5 1344 DS20-0306-P-L5W 4344 |

| vc,m/min | 91.5 | 127 |

| n,rpm | 1080 | 1500 |

| fn,mm | 0.05/0.11/0.05 | 0.08/0.05 |

| 刀具寿命,孔数 | 200 | 600 |

| 刀具寿命,m (英尺) | 14 (46) | 42 (138) |

| 结果: | 客户希望提升钻削性能和获得可靠、安全的钻削加工过程。使用切削速度提升且进给率降低了的CoroDrill DS20,实现了出色的刀具寿命和切屑成形。 |

成功案例

| 零件: | 齿圈,每个零件14个孔 |

| 材料: | 42CrMo,P2.5.Z.HT,CMC 02.2,300 HB |

| 工序: | 通孔,D15,长度:104 mm |

| 机床: | 立式加工中心,ISO 40锥柄 |

| 冷却液: | 乳化液 |

刀具寿命

+1000%

生产率

+146%

| HSS钻头 | 山特维克可乐满 | |

| 刀具 | D15X7D | DS20-D1500L20-07 |

| 刀片 | - | DS20-0104-C-M7 1344 DS20-0104-P-M7W 4334 |

| vc,m/min | 13 | 100 |

| n,rpm | 276 | 2122 |

| vf,mm/min | 69 | 170 |

| fn,mm | 0.25 | 0.08 |

| 切削时间 (分钟) | 21.11 | 8.58 |

| 3金属去除率,cm/min | 24 | 60 |

| 刀具寿命 (件) | 1 | 10 |

| 刀具寿命 (分钟) | 21.1 | 85.77 |

| 结果: | 通过使用CoroDrill® DS20,客户能够提高生产率并缩短生产周期,同时获得明显更好的表面质量。 |

Success Case

| Component: | Connecting rod, 4 holes/component |

| Material: | Steel, P2.5.Z.HT, 230 HB |

| Operation: | Through hole, D: 29 mm (1.142 inch), hole depth: 100 mm (3.937 inch) |

| Machine: | Horizontal machining center, HSK100 |

| Coolant: | Emulsion |

+233%

Tool life

Tool life

|

| Competitor | Sandvik Coromant |

| Tool | - | DS20-D2900L32-04 |

| Insert | - | DS20-0407-C-M7 1344 DS20-0407-P-M7W 4334 |

| vc, m/min (ft/min) | 140 (459) | 130 (427) |

| n, rpm | 1537 | 1428 |

| vf, mm/min (in/min) | 235 (9.25) | 236 (9.29) |

| fn, mm (inch) | 0.153 (0.0060) | 0.165 (0.0065) |

| Time in cut, min | 26 | 25 |

| MRR, cm3/min (in3/min) | 155 (9.46) | 156 (9.52) |

| Tool life, m/edge (ft/edge) | 4 (13.12) | 10 (32.8) |

| Tool life, components/insert | 30 | 100 |

| Result: | Maintaining a similar removal rate, CoroDrill® DS20 was able to achieve a tool life increase of 233% per insert compared to the solution in place. | |

Success Case

| Component: | Gear ring, 91 holes/component |

| Material: | 34CrMoNi4, P2.5.Z.HT, 240 HB |

| Operation: | Through hole, Ø 39 mm (1.54 inch), depth: 229 mm (9 inch) |

| Machine: | Vertical machining center, ISO 50 taper, 20 bar (290 PSI) |

+100%

Tool life

Tool life

+84%

Increased productivity

Increased productivity

|

| Competitor | Sandvik Coromant |

| Tool | - | DS20-D3900L40-06 |

| Insert | - | DS20-0508-C-M7 1344 DS20-0508-P-M7W 4334 |

| vc, m/min (ft/min) | 104 (341) | 160 (525) |

| n, rpm | 850 | 1300 |

| vf, mm/min (in/min) | 0.127 (0.005) 0.08 (0.003) at entry/exit, 3 mm (0.118 inch) | 0.152 (0.006) 0.11 (0.004) at entry, 3 mm (0.118 inch) 0.06 (0.002) at exit, 5 mm (0.197 inch) |

| Time in cut, min | 127.4 | 69.2 |

| MRR, cm3/min (in3/min) | 129 (7.87) | 237 (14.5) |

| Tool life, pcs | Unstable tool life, approximately 1/4 ring per insert edge | 1/2 ring per tool insert edge |

| Result: | With CoroDrill® DS20, the customer obtained a secure and predictable drilling process with good surface quality, better tool life and less insert set-up time. | |

| Competitor | Sandvik Coromant | |

| Tool | D22, special tool | DS20-D2200L25-05 |

| Insert | - | DS20-0205-C-M7 1144

DS20-0205-P-M7W 4344 |

| vc, m/min (ft/min) | 120 (394) | 150 (492) |

| n, rpm | 1736 | 2170 |

| vf, mm/min (in/min) | 104 (4.09) | 174 (6.85) |

| fn, mm (inch) | 0.06 (0.0024) | 0.08 (0.0031) |

| Time in cut, min | 0.88 | 0.53 |

| MRR, cm3/min (in3/min) | 79.2 (4.83) | 132 (8.06) |

| Tool life, pcs | 250 | 250 |

| Tool life, min | 220.78 | 132.47 |

| Result: | With CoroDrill® DS20, the customer increased productivity and decreased cycle time and tool set-up time. | |

| CoroDrill® 880 | CoroDrill® DS20 | |

| Tool | 880-D2200L25-04 | DS20-D2200L25-05 |

| Insert | 880-04 03 05H-C-GR 1044 880-04 03 W05H-P-GM 4324 | DS20-0205-C-M7 1344 DS20-0205-P-M7W 4334 |

| vc, m/min (ft/min) | 130 (427) | 156 (512) |

| n, rpm | 1880 | 2250 |

| vf, mm/min (in/min) | 190 (7.48) | 250 (9.84) |

| fn, mm (inch) | 0.10 (0.0039) | 0.11 (0.0043) |

| Time in cut, min | 12.85 | 9.77 |

| MRR, cm3/min (in3/min) | 144 (8.786) | 190 (11.592) |

| Tool life, holes | 132 | 132 |

| Tool life, min | 51.4 | 39.0 |

| Result: | With CoroDrill® DS20, the customer was able to drill the same amount of holes in shorter time and thereby increase productivity and reduce the cycle time. | |

加入我们,获取最新信息!

现在订阅我们的新闻快讯