CoroMill® MR80

高经济性的面铣和仿形铣削

产品类别,刀体

| 刀体 | Ø | 齿距 | zn | 接口类型 | 刀垫 | 内冷设计 |

| 英制 | 2" | M、H – 等齿距 | 4, 6 | 心轴TDA ¾" | 是 | 是 |

| 英制 | 2 ½", 3", 4" | M – 等齿距 | 6–10 | 心轴TDA ¾" & 1" 心轴TDB 1 ½" | 是 | 是 |

| 公制 | 32 mm | H – 等齿距 | 3 | 圆柱直柄,32 | 否 | 是 |

| 公制 | 40 mm | H – 等齿距 | 4 | 圆柱直柄,32 | 是 | 是 |

| 公制 | 50–100 mm | H – 等齿距 | 4–10 | Arbor TDA 22–32 | 是 | 是 |

| 公制 | 50–100 mm | H – 等齿距 | 6–12 | Arbor TDA 22–32 | 是 | 是 |

产品类别,刀片

| 刀片尺寸 | 刀片槽型 | 材质 |

| 12 | E-L50 | GC1040、GC1130、GC4330、GC4340、S30T |

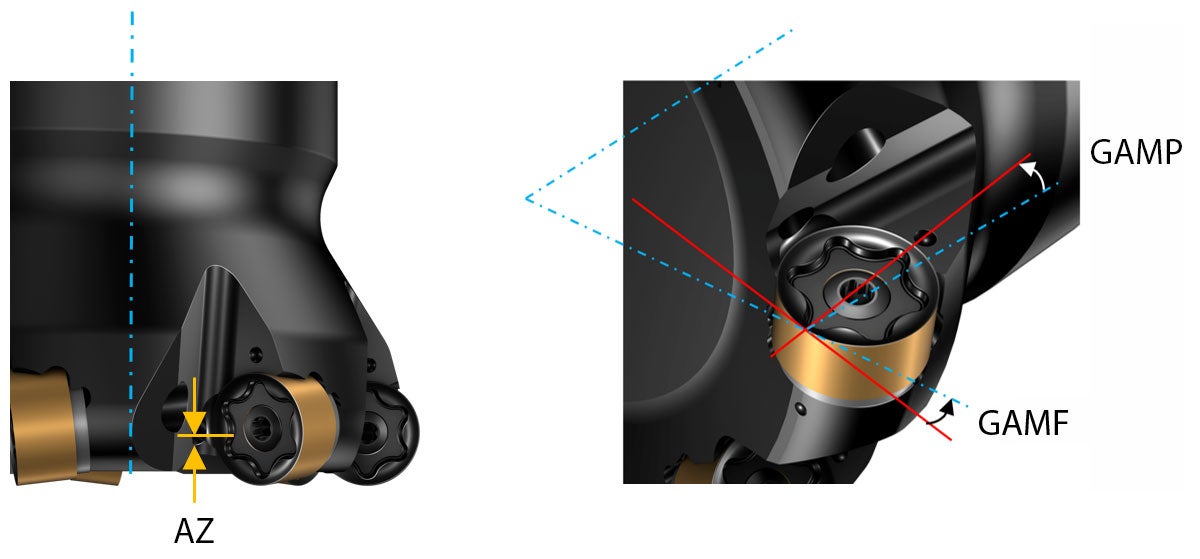

RMPX、AZ、GAMF和GAMP

| 刀体直径 | 坡走角度RMPX | 最大插铣深度AZ,mm (英寸) | 径向前角GAMF | 轴向前角GAMP |

| 32 mm (H) | 0.86° | 0.15 (0.006) | -19° | -7° |

| 40 mm (H) | 0.86° | 0.27 (0.011) | -15° | -7° |

| 50 mm (M / H) | 0.74° | 0.36 (0.014) | -12° / -14° | -7° |

| 63 mm (M / H) | 0.59° | 0.42 (0.017) | -12° / -14° | -7° |

| 80 mm (M / H) | 0.43º | 0.44 (0.017) | -14° / -12° | -7° |

| 100 mm (M / H) | 0.33° | 0.44 (0.017) | -14° / -12° | -7° |

| 2英寸 (M / H) | 0.74° | 0.36 (0.014) | -12° / -14° | -7° |

| 2 ½英寸 (M) | 0.59° | 0.42 (0.017) | -12° | -7° |

| 3英寸 (M) | 0.43º | 0.44 (0.017) | -14° | -7° |

| 4英寸 (M) | 0.33° | 0.44 (0.017) | -14° | -7° |

切削参数,hex建议

| ISO范围 | 参考材料 | 刀片槽型 | hex建议,mm (英寸) | fz建议,mm (英寸) |

| ISO P | MC:P2.1.Z.AN | E-L50 | 0.1 (0.08–0.15) 0.004 (0.003–0.006) | 0.12 (0.09–0.17) 0.005 (0.004–0.007) |

| ISO M | MC:M1.0.Z.AQ | E-L50 | 0.1 (0.08–0.15) 0.004 (0.003–0.006) | 0.12 (0.09–0.17) 0.005 (0.004–0.007) |

| ISO K | MC:K2.2.C.UT | E-L50 | 0.1 (0.08–0.15) 0.004 (0.003–0.006) | 0.12 (0.09–0.17) 0.005 (0.004–0.007) |

注意:fz由ap = 3 mm (0.118英寸) 和ae = 75% DCX计算得出

切削参数,vc建议

| ISO范围 | 参考材料 | 材质 | vc建议,m/min (英尺/分钟) |

| ISO P | MC:P2.1.Z.AN | GC1130 | 240 (215–250) 787 (705–820) |

| MC:P2.1.Z.AN | GC4330 | 280 (255–295) 919 (837–968) | |

| MC:P2.1.Z.AN | GC4340 | 240 (215–250) 787 (705–820) | |

| ISO M | MC:M1.0.Z.AQ | GC1040 | 155 (135–165) 509 (443–541) |

| MC:M1.0.Z.AQ | GC1130 | 225 (200–235) 738 (656–771) | |

| MC:M1.0.Z.AQ | GC4340 | 185 (165–195) 607 (541–640) | |

| MC:M1.0.Z.AQ | S30T | 215 (185–230) 705 (607–755) | |

| ISO K | MC:K2.2.C.UT | GC4330 | 185 (170–195) 607 (558–640) |

注意:vc由ap = 3 mm (0.118英寸) 和ae = 75% DCX计算得出

加入我们,获取最新信息!

现在订阅我们的新闻快讯