Maximized machine utilization

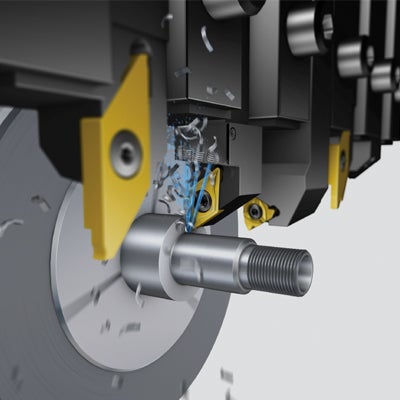

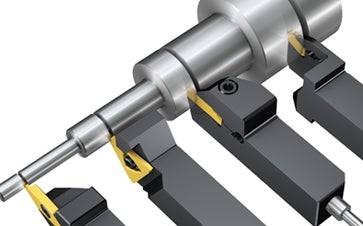

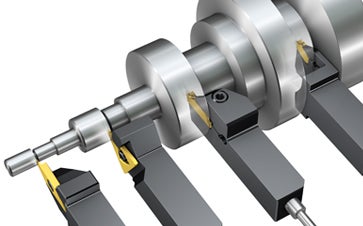

QS™ holding system is a quick change system developed specifically for sliding head machines. The system of tool holders, stops and wedges offer stable tool clamping and secure insert edge position for good repeatability and accuracy.

Process security with high precision

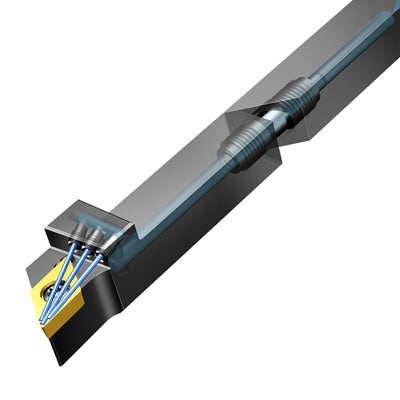

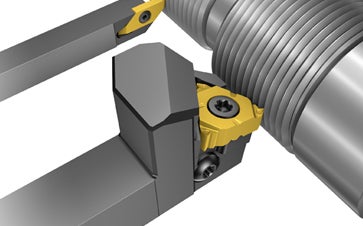

The QS™ tool holders are available with precision coolant, which improves chip control, tool life and component quality. The coolant is easily connected thanks to dedicated coolant connection kits.

Easy handling for reduced downtime

The single screw release function simultaneously pulls out the wedge and holder, for quick tool change and set-up. No diameter adjustment is necessary thanks to the back stop, which ensures close repeatability tolerance for the insert edge position.

Application

- Turning, parting, grooving and threading of small components

- For machining in sliding head machines

- Available for Citizen, Star, Tsugami, Hanwha, Tornos and Nexturn machines

Product range

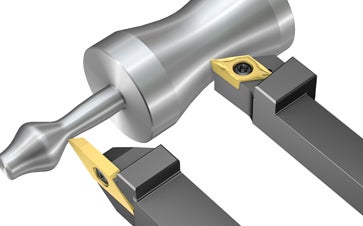

Turning

CoroTurn® 107

Turning and profiling

Diameter: 6–40 mm (0.236–1.57 inch)

RE ≥0.02 mm (0.0008 inch)

CoroCut® XS

Turning, profiling and back turning

Diameter: 1–8 mm (0.040–0.315 inch)

RE ≥RE ≥0.03 mm (0.001 inch)

Parting off

CoroCut® XS

Diameter: <8 mm (0.315 inch)

Cutting width: ≥0.7 mm (0.03 inch)

CoroCut® 3

Diameter: 6–12 mm (0.24–0.5 inch)

Cutting width: ≥1 mm (0.04 inch)

CoroCut® 1-2

Diameter: 12–32 mm (0.5–1.25 inch)

Cutting width: ≥1.5 mm (0.06 inch)

CoroCut® QD

Diameter: ≥20 mm (0.79 inch)

Cutting width: ≥1 mm (0.04 inch)

Grooving

CoroCut® XS

Max. cutting depth: 1.3–3.7 mm(0.05–0.15 inch)

Cutting width: 0.5–2.5 mm (0.02–0.098 inch)

CoroCut® 3

Max. cutting depth: 3–6 mm (0.12–0.24 inch)

Cutting width: 0.5–3.18 mm (0.02–0.12 inch)

CoroCut® 1-2

Max. cutting depth: 6–16 mm (0.24–0.63 inch)

Cutting width: 1.5–3 mm (0.06–0.13 inch)

CoroCut® QD

Max. cutting depth: >16 mm (0.63 inch)

Cutting width: 1–3 mm (0.04–0.12 inch )

Thread turning

CoroThread® 266

Most thread forms

Multi- or single-point profiles

Diameter: 8–40 mm (0.315–1.57 inch)

CoroCut® XS

Thread forms: M, UN, NPT, WH, V-profile

Diameter: 1–8 mm (0.040–0.315 inch)

Highlights

QS™刀柄系统与传统装夹的比较

QS刀柄系统意味着在纵切机床中快换。了解与传统装夹相比,使用该解决方案能够如何迅速地在不同的刀具之间切换。

加入我们,获取最新信息!

现在订阅我们的新闻快讯