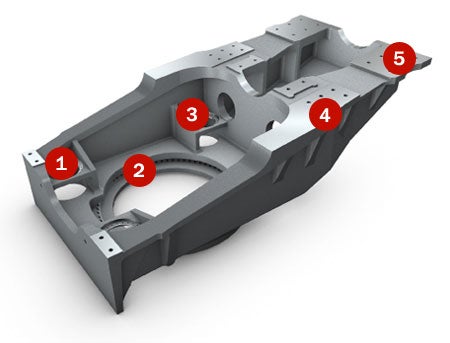

Main frame

1. Face and shoulder milling

CoroMill® 490

is the versatile face and shoulder milling tool that will cut tool costs and inventories whilst offering higher precision and tighter tolerances.

2. Contouring

To rough out the bore the CoroMill® 390 long edge is an excellent choice with high metal removal rate, light cutting and low vibration tendency.

CoroMill® 390

2. Back facing

Machining inside the main frame can be difficult and time consuming. A cost efficient solution is back facing with high precision CoroMill® 331.

CoroMill® 331.

3. Fine boring

Use CoroBore® 825 for the finishing operation. With precision in focus, it is versatile and easy to use with micrometrical adjustments.

CoroBore® 825

4. Drilling

CoroDrill® 880

Just by exchanging a conventional drill with a , you can double the number of drilled holes in the same amount of time.

Its step technology gives outstanding cutting force balance, providing significant improvements in productivity as well as hole quality. This, in combination with high performance grades makes it outstanding when it comes to rapid hole making.

5. Face milling

With its light cutting action, eight cutting edges and shims to protect the cutter body CoroMill® 345 is excellent for every operation - from rough milling of cast surfaces to mirror finishing.

CoroMill® 345