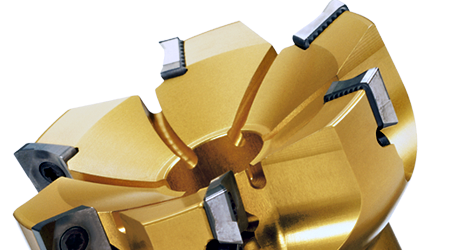

CoroMill® Century is a face mill tool system with aluminium or steel body for high speed machining. The tool is designed with serrated insert interface for safe performance and reduced run-out. The axial position of the inserts can easily be micro set with high accuracy.

Benefits

- High speed machining security by design

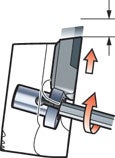

- Intensified chip evacuation through accelerated cutting fluid

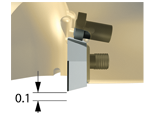

- Easy setting to micro precision within 0.1 mm (0.0039 inch) setting range

Features

- High-alloy aluminium body with Arbor mounting

- Steel body with Coromant Capto® coupling, HSK, Arbor or CIS Arbor mounting

- Insert geometries and grades for all materials including PCD and CBN

- Wiper insert option for high feed finishing

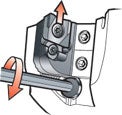

- Exchangeable cassettes for large diameters

Application

- Face and square shoulder milling for ISO N

- CBN grades for high-speed machining in ISO K

Diameter range

- Face mill with aluminium body or steel body: 40–200 mm

(2.000–8.000 inch) - Face mill with exchangeable cassette system: 160–500 mm

(6.000–20.000 inch)

ISO application area

Recommendations

First-choice tool for face milling in aluminium. CoroMill Century also works excellent in hardened steel and ISO K material with the new CBN insert program.

|  |

|

Product range

| 40-200 mm | 11 | 10 mm carbide 2 and 5 mm CB50 2 and 5 mm CD10 |

| 2-8 inch | 11 | 0.394 inch carbide 0.047 and 0.197 inch CB50 0.047 and 0.197 inch CD10 |

CoroMill century cassette system to be quoted

| 160-500 mm | 11 | 10 mm carbide 2 and 5 mm CB50 2 and 5 mm CD10 |

| 6-20 inch | 11 | 0.394 inch carbide 0.047 and 0.197 inch CB50 0.047 and 0.197 inch CD10 |