T-Max® P

Tournage extérieur productif de pièces de moyenne à grande taille

Insert seat

Clean and inspect insert seat for damaged locations and support for cutting edge

Shims and shim seats

Ensure that shim corners have not been knocked off during machining or handling and shim seats should have no edge build up

Contact faces

Check supporting and contact faces, making sure there is no damage or dirt.

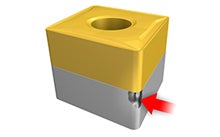

Clamping

In boring operations, it is important to have the best possible clamping. If not supported, overhang will be increased and might create vibration.

Application tips

Recommendations

Insert and system

External operation

| Finishing | Medium | Roughing | |

| Insert shape | C | C | C |

| Insert size | 12 | 12 | 12 |

| Entering angle | 95° | 95° | 95° |

| Clamping | Lever | Lever | Lever |

Internal operations

| Fishing | Medium | Roughing | |

| Insert shape | C | C | C |

| Insert size | 12 | 12 | 12 |

| Entering angle | 95° | 95° | 95° |

| Clamping | Lever | Lever | Lever |

Insert grade

| Machining conditions | P | M | K | S | H |

| Good | GC4415 | GC2220 | GC3210 | GC1105 | CB7115 |

| Average | GC4425 | GC2025 | GC3210 | GC1115 | CB7125 |

| Difficult | GC4335 | GC2035 | GC3225 | GC1125 | CB7135 |

Insert geometry

| Operation | P | M | K | S | H |

| Finishing | -PF | -MF | -KF | -SF | S01525 |

| Medium | -PM | -MM | -KM | -SM | S01525 |

| Roughing | -PR | -MR | -KR | -SMR | S02035 |

Abonnez-vous pour rester informé(e).

Abonnez-vous dès aujourd'hui à notre e-newsletter