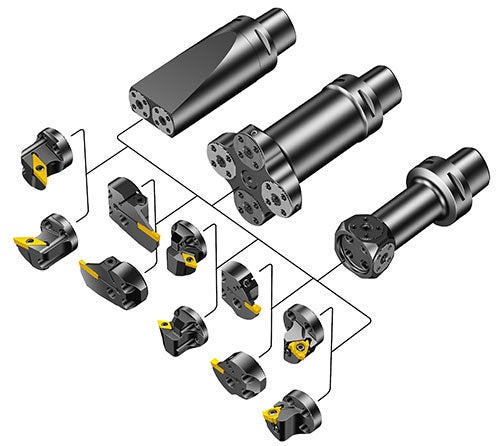

CoroTurn® SL

Modular system of adaptors and cutting heads for internal turning, grooving, threading, boring, and multi-task machining, for hole diameters down to 20 mm. For machining in turning centers, lathes, and multi-task machines.

Choose a suitable adaptor

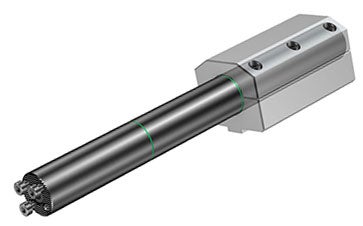

There are several adaptive items and tool holding options to choose from. If working with long overhangs or want to increase productivity, consider a Silent Tools™ damped boring bar.

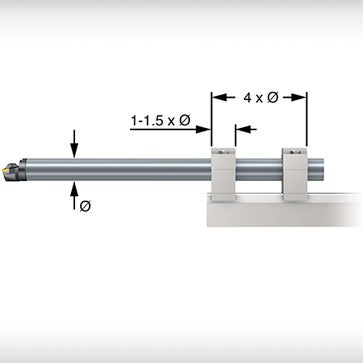

Choose shortest possible overhang

For best performance of your CoroTurn SL tool, always choose the shortest possible overhang.

Select suitable cutting head

Choose cutting head that fits your application (recommendations below). Consider SL70 interface for profiling or pocketing of large components or difficult-to-reach features.

Always use the right torque

Use correct tightening torque when mounting the cutting head.

Application tips

Tips for internal grooving

Long overhangs and poor chip evacuation are two of the challenges with internal grooving. Long overhangs can cause problems with both deflection and vibration while vibrations and poor chip evacuation can cause insert breakages

Turning tool set-up

Learn what to think about when working with long overhangs and how to get an optimal tool set-up.

Machine tools and tooling considerations

Find out how to choose the right spindle interface depending on machine and tooling system considerations and get the most out of your machine.

Minimize vibration with Silent Tools™

You can’t avoid vibration entirely in metal cutting operations, but there are several ways to reduce it. This Silent Tools™ application guide will help you achieve productive machining with minimized vibration.

Recommendations

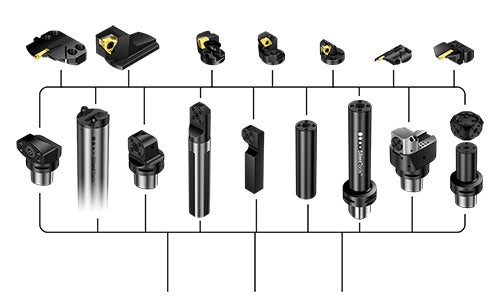

Cutting head recommendations

Get our recommendations for which cutting head to use depending on application. Click on links to learn more about respective product family.

Turning

- CoroTurn® 107 for turning small to medium sized holes, slender components

- CoroTurn® Prime for excellent chip evacuation, for diameters above 40 mm (1.575 inch)

- T-Max® P for turning of large diameter bores

- CoroTurn® TR for profiling

Grooving

- CoroCut® 1-2 for versatile grooving, system includes SL70 cutting heads for machining complex components

- CoroCut® QD first choice for deep grooving on larger components

Face grooving

- CoroCut® QF, first choice for secure face grooving

- CoroCut® 1-2, versatile system for face grooving

Thread turning

- CoroThread® 266 for rigid thread turning

View CoroTurn SL cutting head assortment here

Adaptor system recommendations

- CoroPlex® SL mini-turret – four turning tools in one for turning, grooving or threading

- CoroBore 825 SL for face grooving on non-rotating components

Is your set-up coolant compatible?

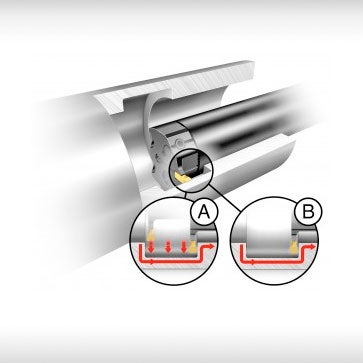

The new generation of CoroTurn® SL cutting heads (SL16 and SL20) seamlessly integrate with the through coolant functionality of the new generation Silent Tools™ turning adaptors, delivering side-oriented internal through coolant to the insert edge.

To utilize the benefits of both products, your set-up needs to be coolant compatible. See the matrix below to find out which cutting heads that can be paired with which adaptors.

| | New generation CoroTurn® SL cutting head, SL16 & SL20 | Old generation CoroTurn® SL cutting head, SL16 & SL20 | CoroTurn® SL cutting head with HPC, SL25 | CoroTurn® SL cutting head, SL25 |

| New generation Silent Tools™ turning adaptor, 16 & 20 mm (⅝ & ¾ inch) | Yes | No | N/A | N/A |

| Old generation Silent Tools™ turning adaptor, 16 & 20 mm (⅝ & ¾ inch) | Yes | Yes | N/A | N/A |

| New generation Silent Tools™ turning adaptor (through coolant), 25 mm (1 inch) | N/A | N/A | Yes | No |

| Old generation Silent Tools™ turning adaptor (side coolant), 25 mm (1 inch) | N/A | N/A | No | Yes |

Old generation Silent Tools™ turning adaptor (through coolant), 25 mm (1 inch) | N/A | N/A | Yes | No |

From diameter 32 mm (1 ¼ inch), all old cutting heads can be used.

Spare part recommendations

Hexagon key boxes

For tightening the hexagon screws on CoroTurn SL cutting heads there are hexagon key boxes, both metric and inch version.

Torque wrenches

It is important to have the correct insert tightening torque, these are the torque wrenches available in our assortment.

| Torque wrench | Torque range | Handle | |

| Nm | In-lbs | ||

| 5680 105-01 | 0.3-1.2 | Straight | |

| 5680 105-02 | 1.2-3.0 | Straight | |

| 5680 105-05 | 3.0-6.0 | Angled | |

| 5680 105-06 | 4.0-8.8 | Angled | |

| 5680 105-03 | 2.5-11.5 | Straight | |

| 5680 105-04 | 11.0-26.0 | Straight | |

| 5680 105-07 | 26.0-55.0 | Angled | |

| 5680 105-08 | 35.4-78.0 | Angled | |

| 5680 099-01 | 3-15 | Angled | |

| C-TK-01M | 20-100 | Angled | |

Join us. Stay updated.

Sign up for our newsletter today