HSK solid and modular tool holding system can be used in spindles with both automatic and manual tool change. Properly applied, HSK offers high consistency in terms of radial and axial accuracy.

Benefits

- Consistent performance

- Light tools compared to ISO-tapers

Features

- Light, short interface performing well at high spindle speeds

- Radial and axial face contact

Application

- Rotating applications in machining centres

- Turning applications in turning centres with turret

- Turning applications in multi-task machines with spindle

Product rangeTurning

Modular tooling

HSK machine interface adaptor | HSK machineinterface adaptor HD | HSK integrated machine adaptor |

|  |  |

| Cx – 390.410 Cx – 390.612 | CX – 390.410 HD | 392.410EH |

Solid tooling

| Face mill holder | Face mill holderCoolant through holder | Silent toolsface mill holder | CoroChuck 930 HD – Heavy Duty | |

|  |  |  | |

| A392.41005 392.41005 | A392.41005C 392.41005C | 392.41005CD A392.41005CD | 930-HAxx-HD | |

| CoroChuck 930 S-Slender | CoroChuck 930 P-pencil | CoroChuck 935 Turning | ||

|  |  | ||

| 930-HAxx-S | 930-HAxx-P |

ER collet chuck DIN 6499 | End mill holderWeldon type | Holder for drills ISO 9766 | Adjustable drill holderISO 9766 |

|  |  |  |

| 392.41014 | 392.41020 | 392.41027 | 392.410227 |

| CoroChuck 970 for synchronized tapping | CoroBore XL adaptor | Blank | Silent Tools™ turning adaptor with CoroTurn® SL |

|  |  |  |

| 970-HAxx | 392.410XL | 392.41050 |

HSK-T tool holders

- Designed for multitask machines equipped with HSK-T

- Spindle size availability: 63 and 100

- Direct spindle assembly without adapters needed

- Short overhang

- Stable process

- Productivity booster due to its rigidity

Integrated HSK tools for boring

| CoroBore 825 | Fine boring head |

|  |

| Haxx-R825A | 392.410 |

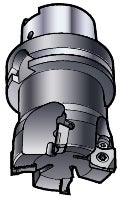

Integrated HSK tools for milling

| CoroMill 490 | CoroMill 590 | CoroMill 690 | CoroMill 790 |

|  |  |  |

| 490-xxxHA | R590-xxHA | 690-xxHA | R790-xxHA |

Use our tooling guidelines below to help you choose between solid and modular assemblies.

Tooling guidelines - solid versus modular

Solid assemblies

|

|

| | |

|

Modular assemblies

|

| Small need | Flexibility | High need | ||||

| | | | ||||

| | | | |

|

||

| | Long assemblies | | ||||

| | | | | |||

| | | | |

|

||

| | Boring | | ||||

| | | | | |||

|

| | | | ||

| | Short gauge line | | ||||

| | | | | |||

|

| | |

|

||

| High batch/volume | Production | Low batch/volume | ||||

| | | | ||||