CoroMill® 178

Solid carbide and PM-HSS power skiving tools for gear and spline production with high output

High productivity and flexibility

Possible to machine the complete component in a multi-task machine or machining centre in one single set-up, which shortens production time, improves quality and reduces handling and logistics costs.

Reduced cycle times

Considerably reduced machining cycle time compared to conventional machining methods, such as broaching, shaping and hobbing.

Efficient also in dry machining

Power skiving runs efficiently also in dry conditions, which eliminates coolant costs and makes for environmental- and operator-friendly machining.

Application area

- Internal and external gears and splines

- Cylindrical spur and helical gears

- Roughing to finishing

- Application range, CoroMill® 178 solid carbide & PM-HSS cutters:

Diameter range: 8–120 mm (0.315–4.72 inch)

Shank diameter: 8, 10, 12, 16, 20, 25, 32, 40 mm (0.315, 0.394, 0.472, 0.630, 0.787, 0.984, 1.260, 1.575 inch)

Module: spline 0.8–5, gear 0.5–3

ISO application area: ISO P - Application range, CoroMill® 178B & CoroMill® 178 cylindrical:

Head diameter range: 15.875, 19.05, 25.4, 31.75, 38.05, 49.9 mm (0.625, 0.750, 1.000, 1.250, 1.500, 1.965 inch)

Shank diameter range: 8, 10, 12, 16, 20, 25 mm (0.315, 0.394, 0.472, 0.630, 0.787, 0.984 inch)

Module: spline 0.8–5, gear 0.5–3

ISO application area: ISO P, ISO S and ISO H

ISO application area

Product range

CoroMill® 178 cylindrical tool

Cutting diameter:

15.4–49.7 mm (0.606–1.957 inch)

Shank diameter:

8–25 mm (0.315–0.984 inch)

Module spline:

0.8–5

Module gear:

0.5–3

Tip radius:

0,4 mm (0.016 inch)

CoroMill® 178 solid carbide shank

Cutting diameter:

8‒100 mm (0.315‒3.94 inch)

Shank diameter:

8‒32 mm (0.315‒1.25 inch)

Module, spline:

0.7‒5 (DP 36‒5)

Module, gear:

0.5–4 (DP 51–6.5)

Tip radius:

0.1 mm (0.004 inch)

CoroMill® 178 PM-HSS shank

Cutting diameter:

8‒120 mm (0.315‒4.72 inch)

Shank diameter:

8–40 mm (0.315‒1.57 inch)

Module, spline:

0.8‒5 (DP 32‒5)

Module, gear:

0.6–6 (DP 42–4)

Tip radius:

0.12 mm (0.005 inch)

CoroMill® 178 solid carbide arbor

Cutting diameter:

45‒120 mm (1.77‒4.72 inch)

Bore diameter:

16‒40 mm (0.630‒1.57 inch)

Module, spline:

0.7‒5 (DP 36‒5)

Module, gear:

0.5–4 (DP 51–6.5)

Tip radius:

0.1 mm (0.004 inch)

CoroMill® 178 PM-HSS arbor

Cutting diameter:

45‒200 mm (1.77‒7.87 inch)

Bore diameter:

16‒40 mm (0.630‒1.57 inch)

Module, spline:

0.8‒5 (DP 32‒5)

Module, gear:

0.6–6 (DP 42–4)

Tip radius:

0.12 mm (0.005 inch)

How to order

Power skiving is available as an engineered solution. For more information, contact your local Sandvik Coromant representative.

In the Sandvik Coromant solution you are offered the tooling, the application support as well as a service offer with technical feasibility consultancy.

Chamfering and deburring tools to complement the power skiving tools are also available.

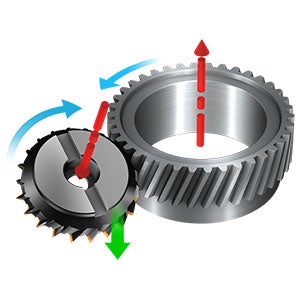

What is power skiving?

Power skiving is a continuous cutting process that enables all machining to be carried out in one single set-up. In essence it is a combination of hobbing and shaping. The intersecting angle between tool and gear axis and the revolution speed is decisive for productivity.

A further advantage of the machining method is its capability to machine close to shoulders, allowing greater freedom in component design.

Highlights

CoroMill® 180 indexable power skiving cutter

CoroMill® 180 is an indexable power skiving solution with fixed inserts.

Automotive transmission

Sandvik Coromant offers tools for most transmission components, backed up with in-depth application know-how.

Join us. Stay updated.

Sign up for our newsletter today