Plunge drilling

What is plunge drilling?

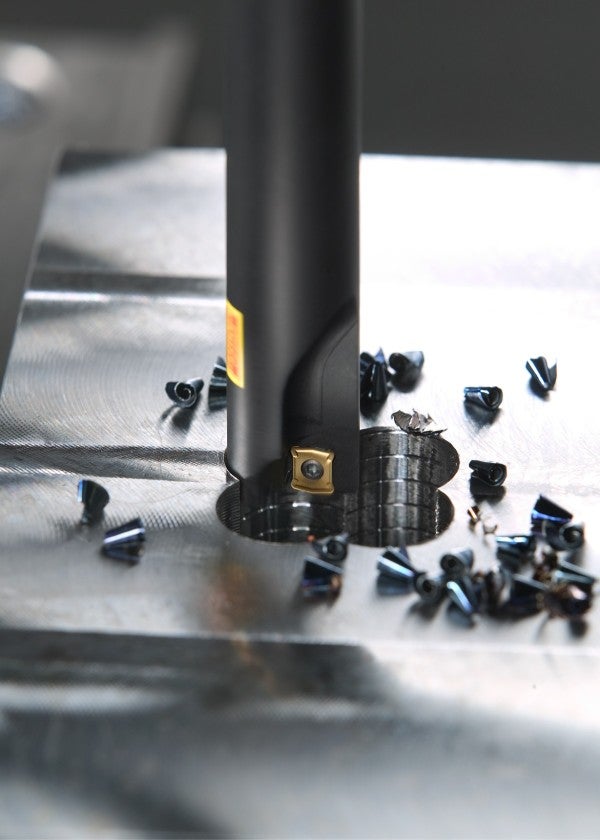

Plunge drilling is an effective method for roughing out cavities. It makes a deeper hole or cavity through repeated axial cuts using a drill or milling cutter and is especially suitable for rough machining. It is power-efficient, productive and reduces demands on the machine tool spindle as the main cutting forces are directed axially along the spindle. Internal plunge milling is started by drilling a hole for the plunging tool.

Choice of tools

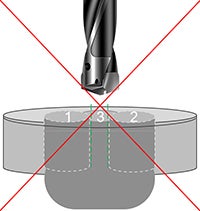

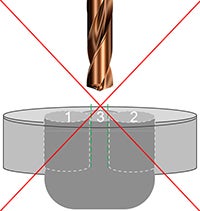

Symmetrical drill point tools (exchangeable-tip and solid drills) should not be used for plunge drilling.

Indexable drills

Indexable drills are used for centre cutting with two inserts and are very productive. Seventy percent of the drill diameter can be applied to the next overlapping cut if you use the plunge drill at full indexable insert drill cutting data. Metal removal rate is high.

Plunge milling is similar to plunge drilling using an indexable insert cutter, a round insert cutter or a solid carbide drill. However, a milling cutter has limited step-over – only half of the axial insert cutting edge length. It can be an interesting alternative when diameters are large enough to have a number of teeth engaged to provide high feeds.

Strategy

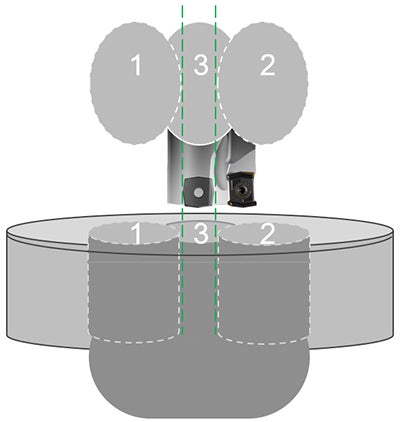

- Avoid a large overlap which allows the chips to fall out of chip channels

- Drill solid holes first (1 and 2)

- Distance between holes is recommended to be set so that the central insert remains in full engagement

- Webbed holes (3): Use very low cutting data with soft entry

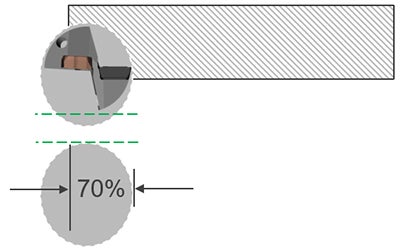

- Edge plunging, ensure 70% of the drills diameter is in engagement

Pocket plunging

Edge plunging