Find the right tool for any job

CoroPlus® Tool Library offers customized and easily shareable tool recommendations, based on material, operation, and tool type

GibbsCAM® 2025 seamlessly integrates with CoroPlus® Tool Library, making the import of tool geometries and cutting data more efficient than ever before. A cutting-edge CAM software for programming CNC machine tools with the power and flexibility to make parts the way you want. With GibbsCAM, CNC programming is flexible, fast, reliable, and efficient.

By using CoroPlus® Tool Library together with GibbsCAM®, users can streamline the design and production of their components with increased speed and effectiveness.

CoroPlus® Tool Library fully integrated with the current version of GibbsCAM® 2025—allows access to a comprehensive selection of cutting tools.

CoroPlus® Tool Library is embedded and ready to utilize in Gibbscam® 2025.

Access to a cutting library, importing 3D models and cutting data to GibbsCAM® 2025.

CoroPlus® Tool Library offers customized and easily shareable tool recommendations, based on material, operation, and tool type

Import tool assemblies directly into GibbsCAM® 2024 via CoroPlus® Tool Library. This streamlines the process, enabling users to effortlessly locate and utilize the most suitable tools.

Thanks to 3D models and recommended cutting data, users can optimize the machining process and yield better results without making manual entries.

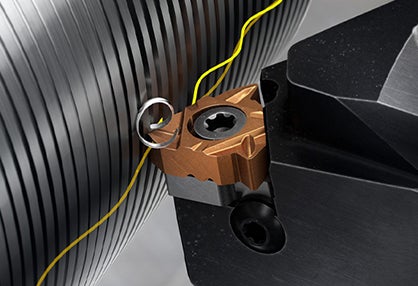

An advanced threading technology that reduces vibration, increases tool life, and improves surface finish.

It offers enhanced process security and versatility across various materials and applications. The technology ensures precise, efficient, and reliable threading, boosting overall performance and productivity in manufacturing operations

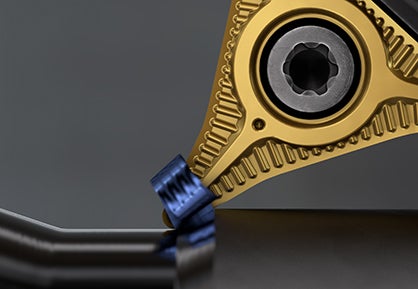

PrimeTurning™ allows turning and facing in all directions, delivering dramatic increases in high-volume production.

PrimeTurning™ has proven to deliver cycle time reductions of up to 50%, and up to 500% increase for insert tool life.

Y-axis turning is a 3-axis simultaneous turning method in which the tool rotates around its own center.

The main cutting forces are directed into the machine spindle, offering high process stability. By applying all-directional turning, it is possible to finish complex shapes in a single cut without "blend points".

Sign up for our newsletter today